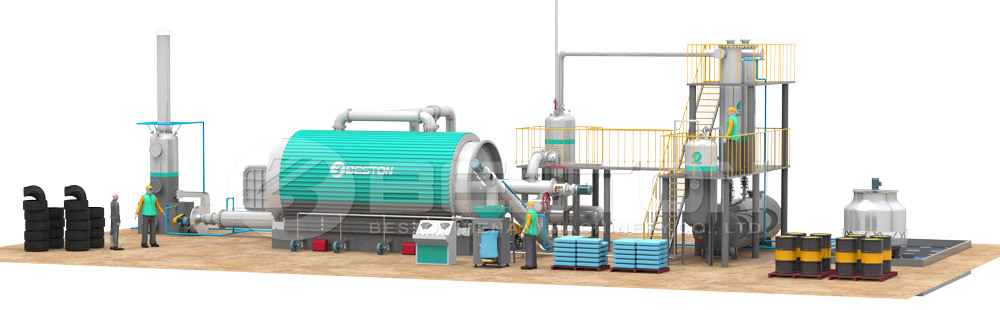

Waste tires and plastic are transformed into fuel oil and carbon black through the process of pyrolysis. Fuel oil and carbon black are in high demand in the industrial sector since fuel oil can be further refined to produce diesel. Fuel oil is also commonly used for heating purposes in several industries. On the other hand, carbon black has many uses and is in great demand these days. If you have easy access to waste tires and plastic components, you can make a handsome profit by investing in a pyrolysis plant. If a full-size plant is not within your budget range, you can always opt for a small pyrolysis plant. Depending on the volume of waste tires you have, a small pyrolysis plant should be a great investment opportunity for you.

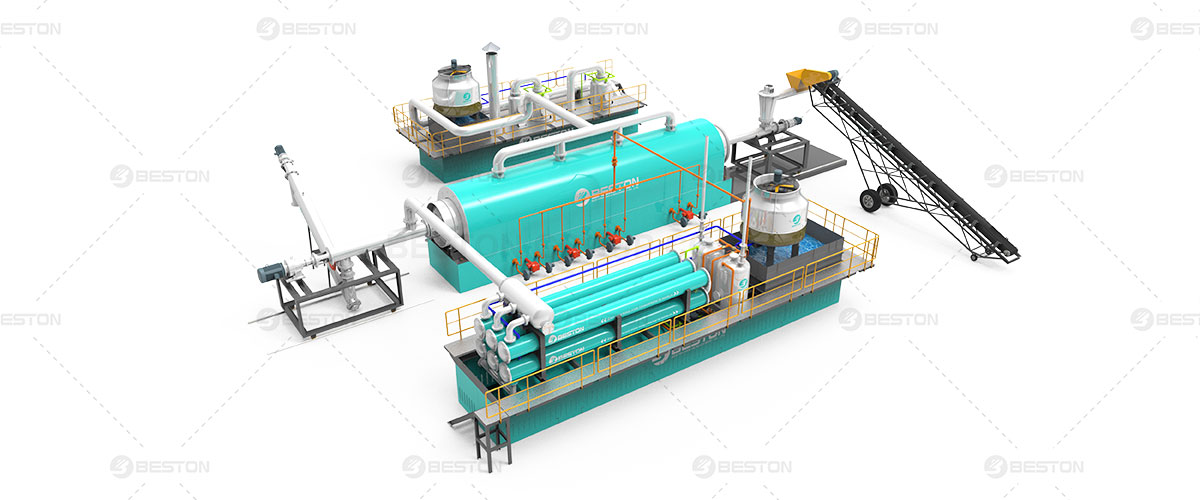

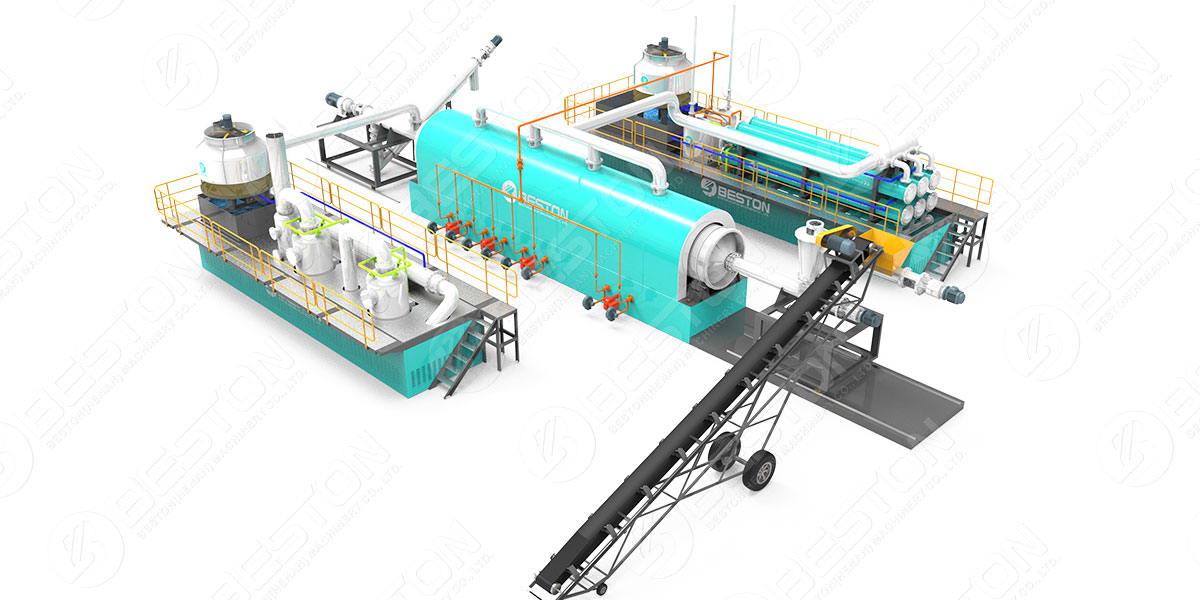

Waste Pyrolysis Plant For Sale

There are hundreds of manufacturers and suppliers of small pyrolysis plants across the globe. But all of these companies don’t produce quality pyrolysis machines. Your extensive research is crucial to selecting the right pyrolysis plant to suit your business. There are many important factors to consider before you shop for the best small machine for pyrolysis. This article provides information on what you need to consider when buying a small pyrolysis plant for sale.

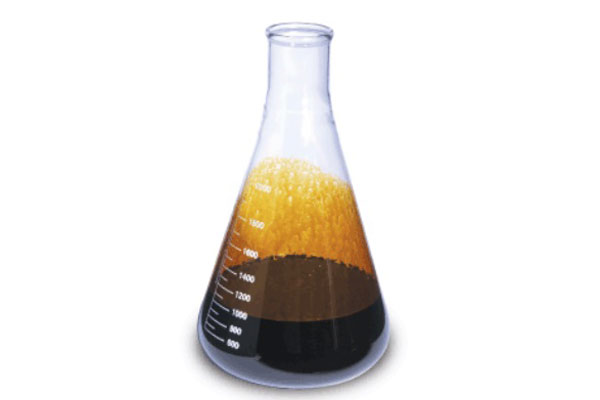

Pyrolysis Oil

The reputation of the manufacturer or supplier is one of the most important factors to consider when shopping for a small pyrolysis plant for sale. Does the manufacturer or supplier have a strong reputation in the market? If so, it indicates the manufacturer takes its reputation seriously and will not provide low-quality products just to make a quick buck in the process. Your business partners, colleagues, and trustworthy friends are the best people to give you a reference in this regard. Getting a personal reference from someone you trust is the best way to buy a quality pyrolysis equipment at an affordable price. Even though you might be able to find cheaper products in the market, the saving should not come at the expense of lower quality materials, which means the machine isn’t durable after all. If you can’t afford a brand new pyrolysis plant, you can easily shop for a second-hand plant rather than compromising on quality to save a few hundred dollars in the process.

The aforementioned article provides information on some of the most important factors to consider when shopping for a small pyrolysis plant for sale. You can learn more about this machine and send feedback on Beston website: bestonasia.com.