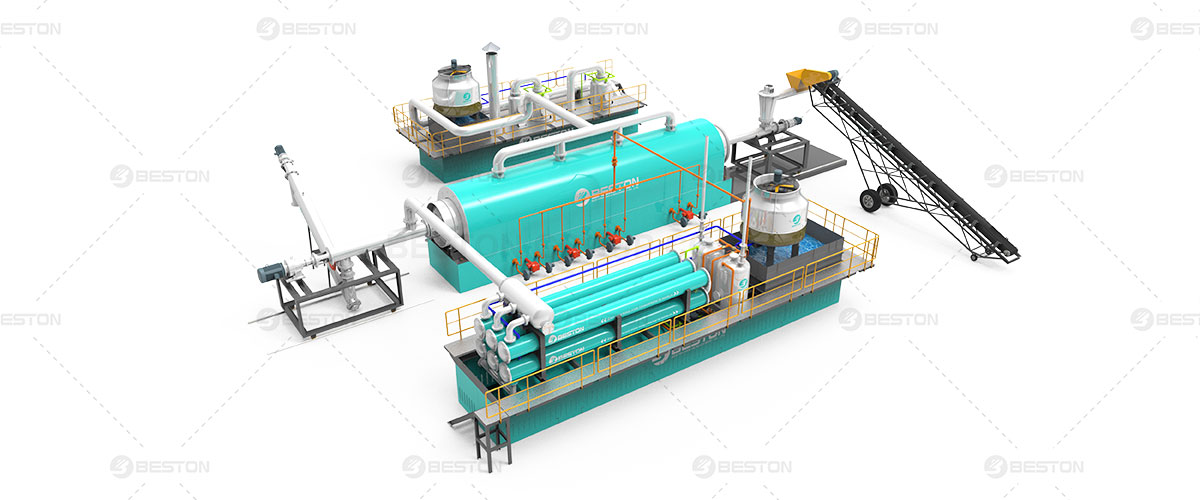

Additionally, you want to know your options concerning types of processes that exist for recycling waste tires and other materials. Quite a few businesses these days are counting on small scale pyrolysis plants, which are known for being cost-efficient and more environmentally friendly.

Planta de Pirolisis

Cost Efficient

One of the best benefits of the small scale pyrolysis machine(planta de pirólisis) is that it produces its own fuel. The liquid fuel oil, otherwise known as pyrolysis oil, is used to fuel the machine. The pyrolysis process produces much more oil than is needed for fuel. Therefore, you can sell the rest for profit, or you can choose to purchase additional equipment to turn the pyrolysis oil into diesel fuel, which can net you even more money.

The pyrolysis process also produces hydrocarbon gas, which can also be used as fuel for the machine or other departments within your facility. Furthermore, profits continue to pile on when you start tapping into the market for solid carbon or “carbon black.” The icing on the cake is when recycling waste tires, you also net some steel, which further increases your revenue.

Labor Costs

Small scale pyrolysis plants(planta pirolisis llantas) do require more manual labor than continuous pyrolysis machines; however, with the right business plan, you can still expect to turn a pretty profit. They also require a less substantial investment initially, and that better fits the plans for most smaller organizations. Quite a few manufacturers produce these plants, so it is imperative that you get a good feel for the market.

Planta de Pirólisis en Mauritania

A small scale pyrolysis machine must be prepped in between each round, and that is where the extra manual labor comes into play for these machines. Determining your sweet spot for labor costs according to your business plan is just as important as pricing these plants.

The Pyrolysis Process

Understanding the logistics is one thing, but to bring your operations to profitability, you want to familiarize yourself with the finer details. For example, as you compare various machines(https://www.bestoneco.com/), pay attention to the oil yield, operating pressure, host speed, structure form, capacity, transmission mode, equipment depreciation, and other specs.

Final Thoughts

Deciding whether a small scale pyrolysis machine(maquina para pirolisis de plasticos) best fits your facility is crucial to your business plan. Continuous pyrolysis machines require a more substantial investment, but they are able to handle the type of volume that can dramatically increase your profits from recycling waste tires and other materials. Is the small scale pyrolysis plant your best bet?