Have you ever heard of a continuous tyre pyrolysis plant? Are you aware of the pyrolysis technology? If you’re reading this article, chances are you are either aware of this technology or want to know more about it and that is how you ended up on this page. You are at the right page as we are going to discuss the science behind this technology and how the continuous tyre pyrolysis plant is helping in getting rid of one of the biggest pollution problems on the planet.

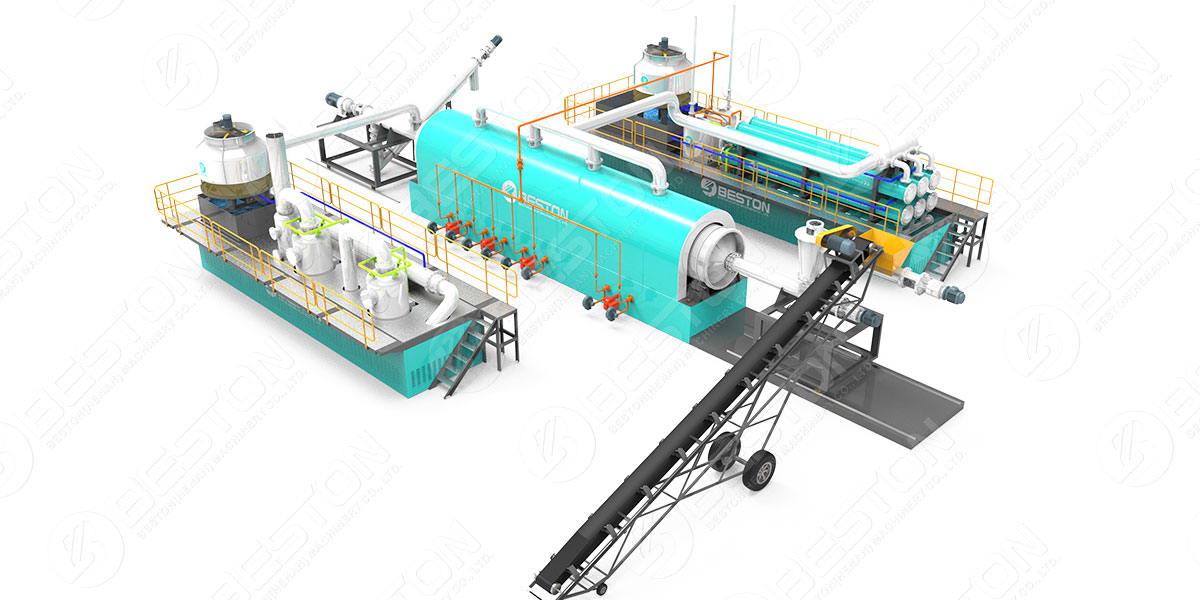

3D Layout of Continuous Pyrolysis Plant

What is Pyrolysis Technology

As a chemical process, it is known as a thermochemical treatment. This process is applied to organic products. In this treatment, the organic matter heated at high-temperature in the absence of oxygen which leads to certain chemical processes. In short, the organic material decomposes and disintegrates in this process. This thermal decomposition results in formation of new molecules as the larger molecular chains are broken down in the process and it creates new products with superior character.

Certain factors affect the success of pyrolysis process. Some of these factors include composition of the material undergoing thermal decomposition, temperature used in the process, amount of time for which the material remains in the pyrolysis chamber as well as the physical structure and size of the material being subjected to pyrolysis. Click here to know more about Beston products.

Now that you’re aware of the pyrolysis process, let’s dive into a continuous type plant. These processing plants, similar to many other processing plants, are mainly of 2 types: batch plants and continuous plants. The continuous plant is the type where processing takes place continuously without any breaks. It offers a number of advantages over a batch plant.

One of the biggest advantages is that it has a much higher processing capacity as it is able to continuously process raw material. However, it also has the limitation that the raw material being fed to the pyrolysis chamber needs to be consistent in quality. If the raw material isn’t consistent, the end result isn’t going to be as good as you would get in a process with similar quality raw material. Processing of different kinds of raw material requires different settings in terms of temperature and other parameters. This is why, investing in a continuous tyre pyrolysis plant makes a lot of economic sense when you have access to a huge quantity of raw material.

BLJ-10 Pyrolysis Plant Shipped to Canada

Since we are discussing a tyre pyrolysis plant, the raw material which is going to be fed into the pyrolysis chamber is going to be waste tyres. Waste tyres are a big pollution problem across the globe. Waste tyres are often thrown into landfills. Since a variety of chemicals are used in the production of a rubber tyre, those chemicals have the potential to leech into the ground and pollute groundwater. Use of pyrolysis technology for processing of waste tyres presents an opportunity to solve the problem of pollution caused by waste tyres in a profitable manner.

To conclude, a continuous pyrolysis plant is used for converting waste tyres into pyrolysis oil and carbon black. Pyrolysis process causes thermochemical decomposition of larger molecules into smaller molecular chains leading to production of fuel oil and carbon black. All these products are in great demand which makes investment in a continuous pyrolysis plant a profitable opportunity for resourceful entrepreneurs. More information on the pyrolysis machine.