The popularity no-pollution tire recycling plants has been on the rise around the world, as more and more populations are waking up to the dangers of environmental pollution, declining natural resources, and limited space on landfill sites. The waste recycling industry is now a very profitable industry in many countries, as waste disposal facilities have adopted new technology, such as tire pyrolysis, to convert waste into profitable products. More information on tire recycling plant for sale here.

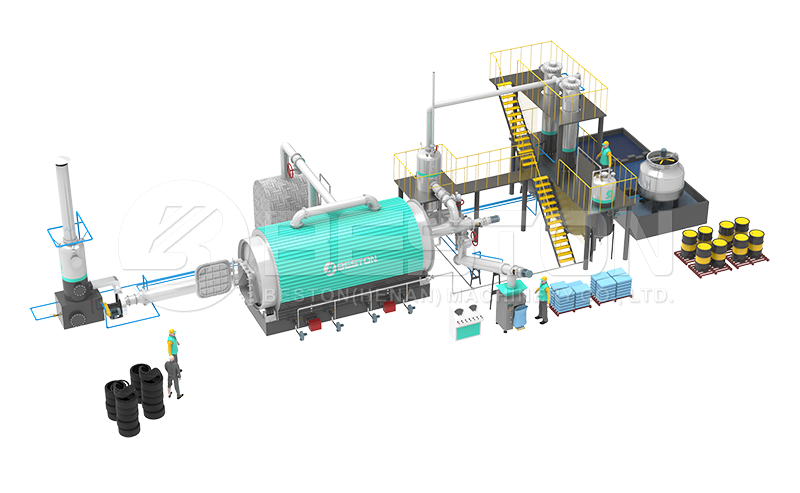

Tire Recycling Plant for Sale

The disposal of waste tires in a major problem in many countries. The tire waste from Europe, the USA, and Japan alone exceeds 6 million tons every year. What’s more, as the automotive industry continues to grow, the quantities of scrap tires requiring disposal or recycling on an annual basis is certain to increase.

Conventional methods of tire disposal can cause lots of environmental problems. When tires sent to landfill sites, for example, they can trap methene gas, which causes them to bubble, expand, and damage landfill site lining. The lining is there to stop contaminants entering ground water and local surfaces, so any damage becomes a big environmental concern.

Fortunately, tire to oil machines now provide an alternative way to recycle waste tires in an eco-friendly manner. With a modern recycling plant for sale, zero toxic emissions are produced during the pyrolysis process. Materials that can be extracted from tires via pyrolysis include combustible gas, tire oil, steel wire, and carbon black. Click here to know more: https://bestonpyrolysisplant.com/.

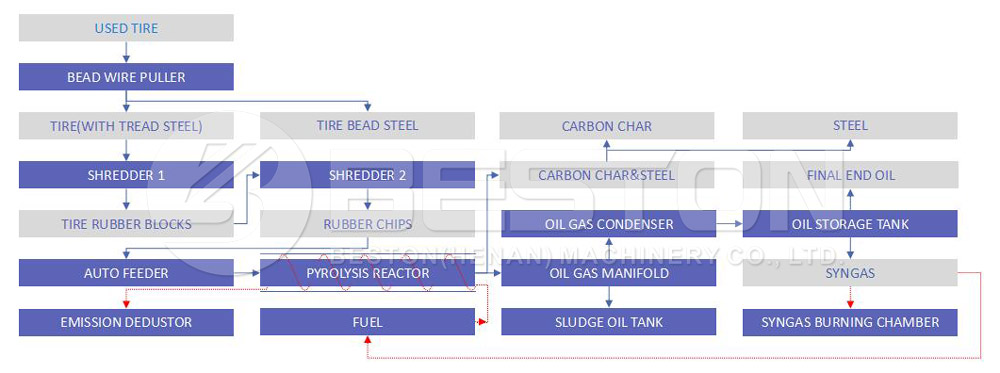

Firstly, the steel wire is manually removed from all tires to prevent damage to the reactor. The tires enter a grinding machine or shredder where they are chopped into small pieces. The shredded material is then fed into the pyrolysis reactor. The reactor is an oxygen-free chamber that is heated to extreme temperatures. As the temperature inside the reactor approaches around 280 degrees, oils in the material begin to vaporize. As the temperature increases, oils of different viscosities continue to vaporize. As the oil vapor enters the manifold, light oil is separated from heavy oil. The heavy oil is pumped back into the reactor for further pyrolysis. Meanwhile, the light oil moves into the condensing system where it is liquified into fuel oil.

Tire Recycling Plant For Sale Online

There are lots of waste tire pyrolysis machines for sale online. The great thing about buying a scrap tire recycling machine online is that you can avail of some of the best prices from global manufacturers and distributors. When it comes to comparing different tire recycling plant machinery, it’s vital that you check out model specifications in detail. Some of the core parameters to compare include working method, power rating, daily capacity, cooling method, floor area, reactor size, reactor pattern, working life and more.

Waste Tire Recycling Process

It’s important to note that pyrolysis machines can be used to recycle a wide range of waste materials besides waste tires, including rubber, plastics, industrial sludge, medical waste, MSW, etc. Recycling facilities that need to process multiple tons of waste each day need to look for continuous pyrolysis reactors. Some of the best models can process over 24 tons of waste each day.