Charcoal making machines are abundant. There are many countries that make these, allowing the people that own them to produce as much charcoal as they need. Whether you choose something that is large, or extremely small for your business, you can produce an adequate amount for your business. If this is for personal use, producing charcoal will be easy. You simply need a large quantity of organic materials to use. Eventually, you will locate a business that will provide you with an affordable charcoal making machine of your very own.

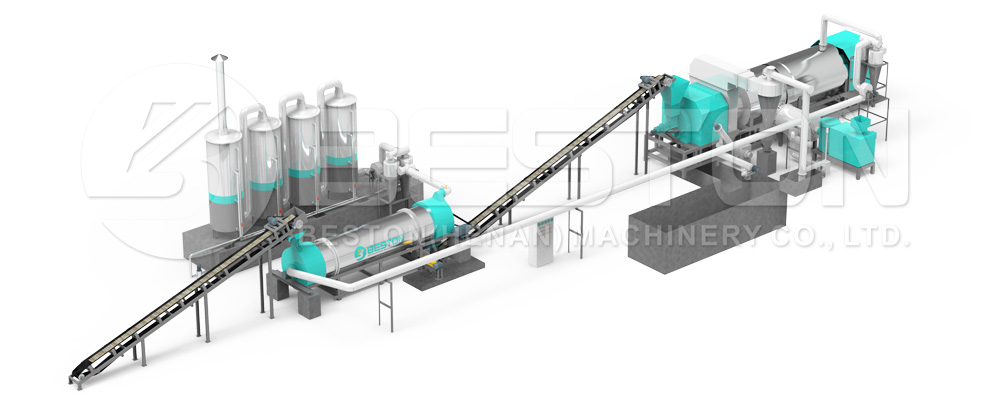

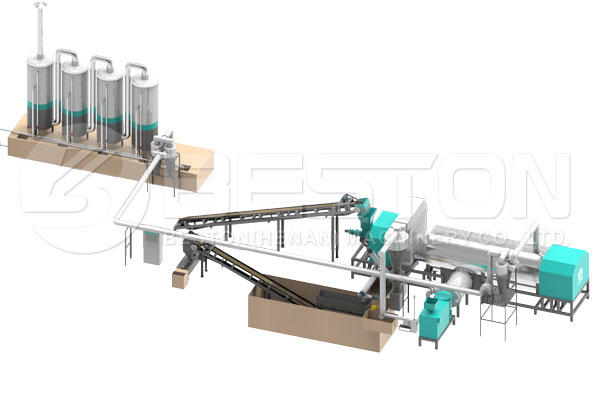

Charcoal Making Machine

How Do They Make Charcoal For You?

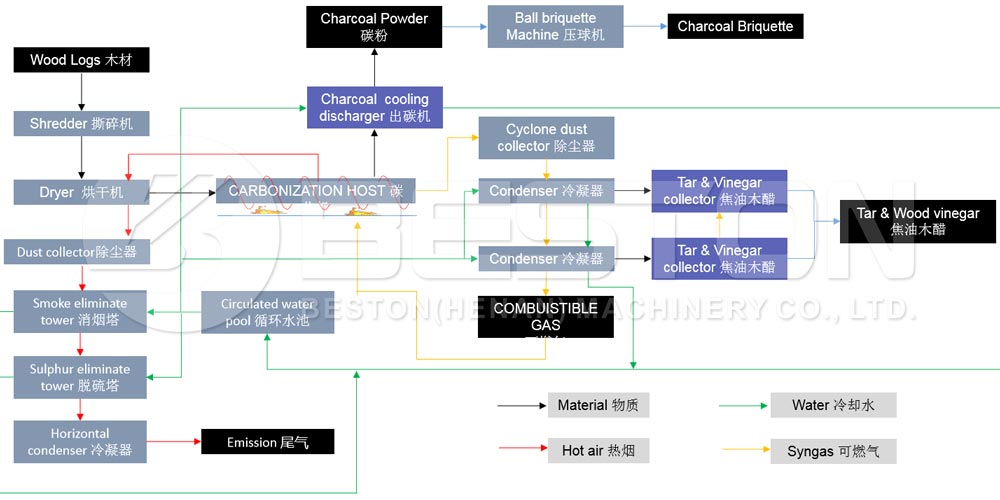

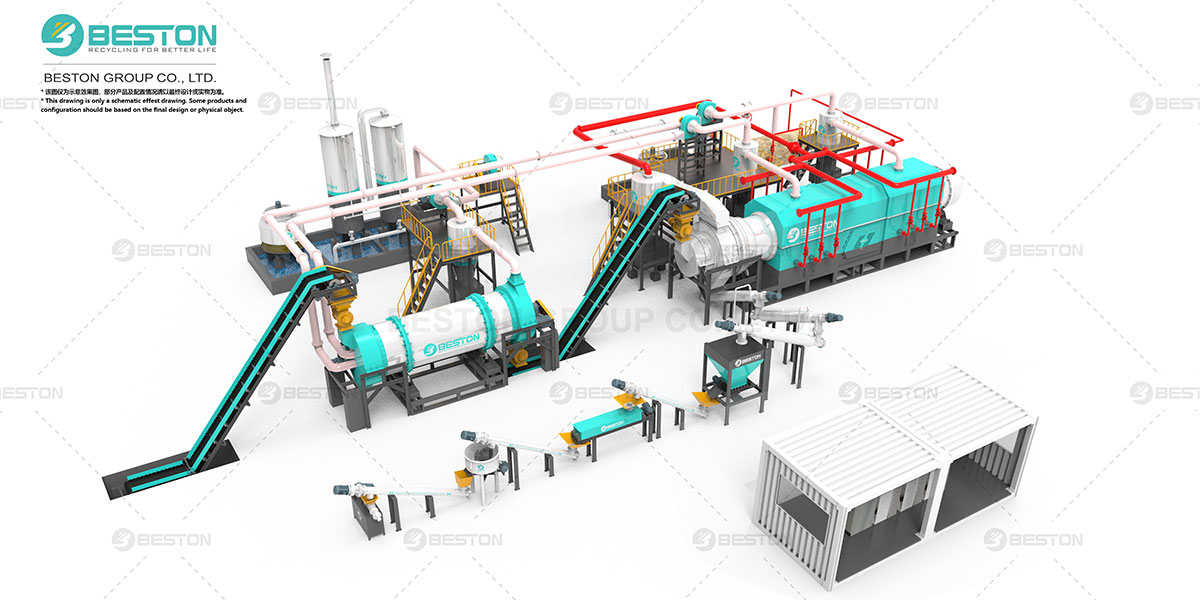

Producing charcoal may take several hours for you to complete the process. Most of these machines are powered by some type of electric motor. You will need to convert the material that you are placing into the charcoal making machine so it is small enough to go through changes in the reactor. There will be no oxygen as part of this process. It is the heat which causes a chemical process to occur. You will end up with both liquid and solid burnable fuels. It just depends on how large the biochar machine is when deciding on how much material you are going to make. It is the pyrolysis process that makes this possible.

What Is The Pyrolysis Process

This process is relatively simple. The combination of heat, and organic materials, will lead to the creation of charcoal. It is the byproduct of this chemical process that can only occur without oxygen. You can then start to produce as much fuel as you need. It will enable you to fuel your business or provide heat for other people. One you have found several of these companies, you can choose the one that offers you the best deal. More information on biochar production equipment here.

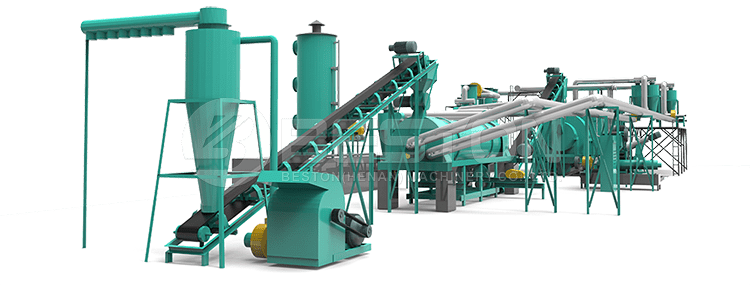

Charcoal Briquettes – Stick Type

How To Find The Companies That Sell Them

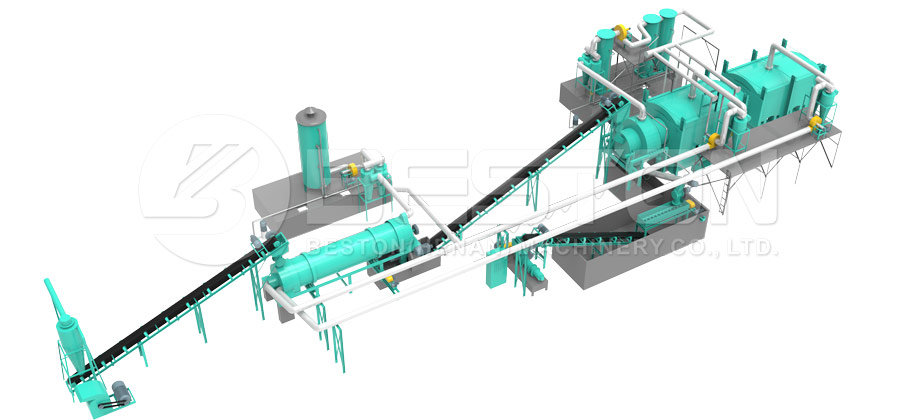

Most businesses that specialize in the production of pyrolysis machines are numerous. They can be found worldwide. Your objective is to locate a company that makes both small and large systems for producing charcoal. Whether you need the liquid fuel that it will also produce, or the solid charcoal that you will burn, all of this can be produced very quickly. It must be an efficient system, one that can provide you with tons of this material which will be easy with either a pyrolysis plant or machine.

Creating charcoal is a very simple process if you have the right machinery. It will only take a few minutes of your time. To locate the best company that offers you a good deal on these machines, you must compare as many companies as possible. Not all of them are going to offer you a low price on these systems. The larger ones tend to be the most expensive. You will need a place to house all of the machinery for the entire system to work. Most importantly, you do need to find a source for this organic material that you will convert. Whether this is sawdust, coconut shells, plastic, or even solid waste, you will soon have more than enough charcoal to use for yourself or for your business. If you want to run a small business, see the small charcoal making machine here.