If you live in a region with abundant biomass waste material, investing in a charcoal making machine could be rewarding. Charcoal has a huge industrial and residential demand due to its efficiency as a fuel. Another benefit of converting various kinds of waste like rice hull, coconut shells, etc., into charcoal is that it helps reduce wastage.

There are numerous companies that provide the charcoal making machine, but not all of them are of high quality. As such, it’s imperative to carefully consider the varying factors in order to pick the right equipment for your new venture.

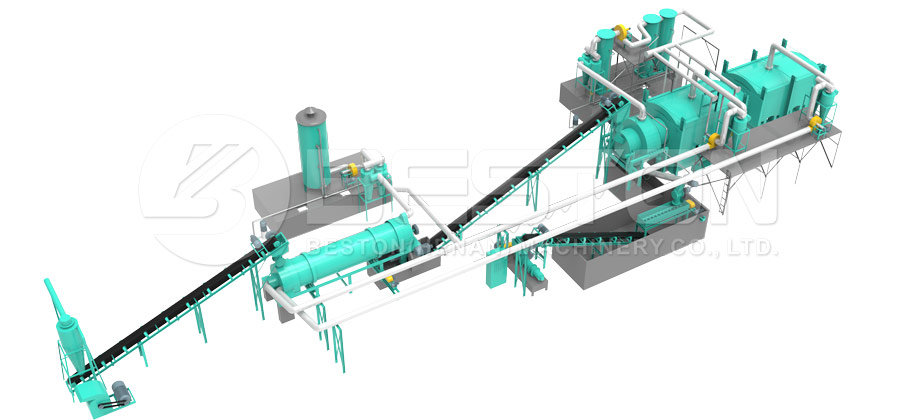

Things to Consider When Buying a Charcoal Making Machine

1. Design

The design of the apparatus is one of the most vital factors to keep in mind. Some of the machines in the market aren’t designed to be as efficient, while others meet this condition. Efficiency in manufacturing implies to the ratio of the final product to the raw materials.

For example, some charcoal makers are capable of converting up to 35 percent of the raw materials, while others can only do a maximum of 25 percent. The best way to get the machine’s efficiency is to assess the specs on the manufacturer’s site. Ideally, look for reviews and testimonials from past clients. Click here to know more: https://bestonpyrolysisplant.com/.

2. Safety

Charcoal is made through a process called pyrolysis. This entails very high pressure, and so, safety is vital. Safety depends on the quality of the materials used to make the machine and also measures implemented to ensure the operators are always safe. This includes an array of sensors like thermometers, pressure gauges and other instruments that help the technicians run the charcoal making machine in a sound and safe manner.

Charcoal production, as expected, releases various gases and other contaminants. If released outdoors, they cause pollution that may attract fines, depending on the country’s pollution standards. As such, it is imperative to ensure the machinery you are getting is designed with minimum pollution in mind. It should have adequate coolers and filters to ascertain the safe elimination of pollutants. Find eco-friendly machine from reliable coconut shell charcoal machine manufacturers.

4. The Price

Of course, price is one of the primary things to consider. However, you should also pay attention to the company’s reputation. You’ll come across companies selling this machinery at a cheaper rate, as compared to other more reputable manufacturers. As with most things in this life, cheap is often disappointing, and in this regard, it equates to poor customer service. So make comparisons, read reviews, and make an informed decision even if the price is a major factor.

Charcoal Making Machine to Ghana

5. Customer Service

Charcoal making machines have several moving parts, and so, it is bound to wear down over time. As such, it’s imperative to have readily available spare parts to keep it running and reduce downtime. Ideally, the manufacturer should provide the necessary training to operate the machinery at maximum efficiency.

If you are looking to invest in a charcoal making machine, it’s important to take precautions and do your homework. The above-mentioned tips should help make the task easier. Seek out more information from the blog: http://chinabeston.zohosites.com.