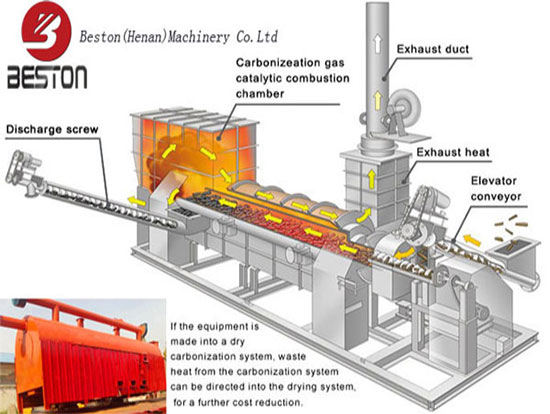

When you want to get rid of waste biomass you are going to need biochar pyrolysis equipment to burn the biomass so you can move on with things. This equipment is easy to use and it is very powerful. The plant can process many different types of biomass like waste wood, rice husks, and coconut shells. The biomass is free or very cheap and you can create charcoal out of it that you can sell for a nice profit.

Biochar Pyrolysis Equipment

The pyrolysis plant generates charcoal from biomass quickly. The plant is an affordable way to produce a lot of biomass for an affordable price. You can get a lot done with this plant and it allows you to make money in a variety of ways. The biomass is a waste material that would end up in the landfills so it is important that you get rid of it and turn it into something else.

You can save so much money with this machine and you can do a lot of things with the machine. This machine is a great investment in your business and you can easily get a lot of things done with it. The machine is going to help get waste products out of the environment and this means that you can save money and produce charcoal.

The charcoal is high-quality. It can be used in a variety of ways. The charcoal is used for cooking, heating, and it is also an ingredient in many products like ink and fertilizer. You will find that you can use the pyrolysis plant in a variety of ways and it can give you a very good return on your investment. It is important to invest in equipment that is going to help you make more money and will ensure that you get a lot done. The plant can help you in a variety of ways and it will give you what you need.

Charcoal from biomass

The plant allows you to produce all of the charcoal you need and it can do it quickly and easily. This plant is going to increase your income and you can make a lot of money when you invest in this plant since it is so efficient. The plant doesn’t cost a lot of money to run and it also heats up quickly.

The continuous pyrolysis plants are the best deal because this plant runs around the clock and will produce charcoal 24 hours a day. You never have to let the plant rest and it allows you to produce all of the charcoal you need. This plant helps you save a lot of money and you can easily take care of your needs when you choose this machine. The machine gives you everything you need to make charcoal and it won’t take a long time to create the charcoal that you need.