Are you trying to decide if it makes sense to purchase a sawdust pellet making machine? Because this can be a significant investment, it can be helpful to look at the benefits that equipment like this can offer before making any sort of equipment. These are just some of the many advantages that the right equipment can offer you.

These Machines Are Easy To Clean And Transport

Since you’ll be working with sawdust, you can expect that your equipment will be dirtied as it is used. Thankfully, this shouldn’t cause any issues for you. The majority of the equipment you’ll see on the market can easily be disassembled, making it simple to clean.

Beyond that, it will be easy for you to transport the equipment as needed. If you need to move the equipment to a new location or want to use it directly on a job site, you’ll be able to do this without an issue. This is flexible ring die wood pellet machine that is well suited to many applications.

You’ll Be Able To Put Sawdust Waste To Good Use

If you already produce sawdust waste, this equipment is an excellent way for you to recycle that waste and turn it into a useable material. There is no reason to throw away the sawdust that you produce. With the right equipment, it still has plenty of value.

Even if you don’t produce your own sawdust waste, you should be able to get access to sawdust without much of an issue. You can produce pellets for your own use, or you can opt to sell these pellets to others.

There Are Numerous Options On The Market

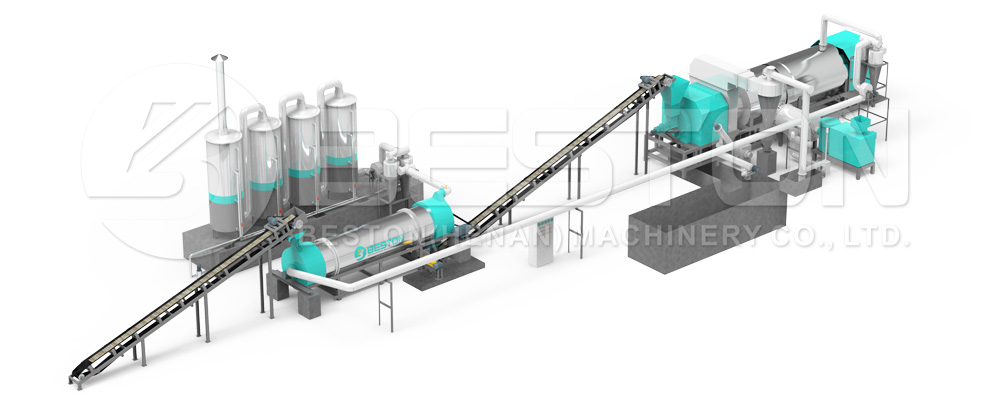

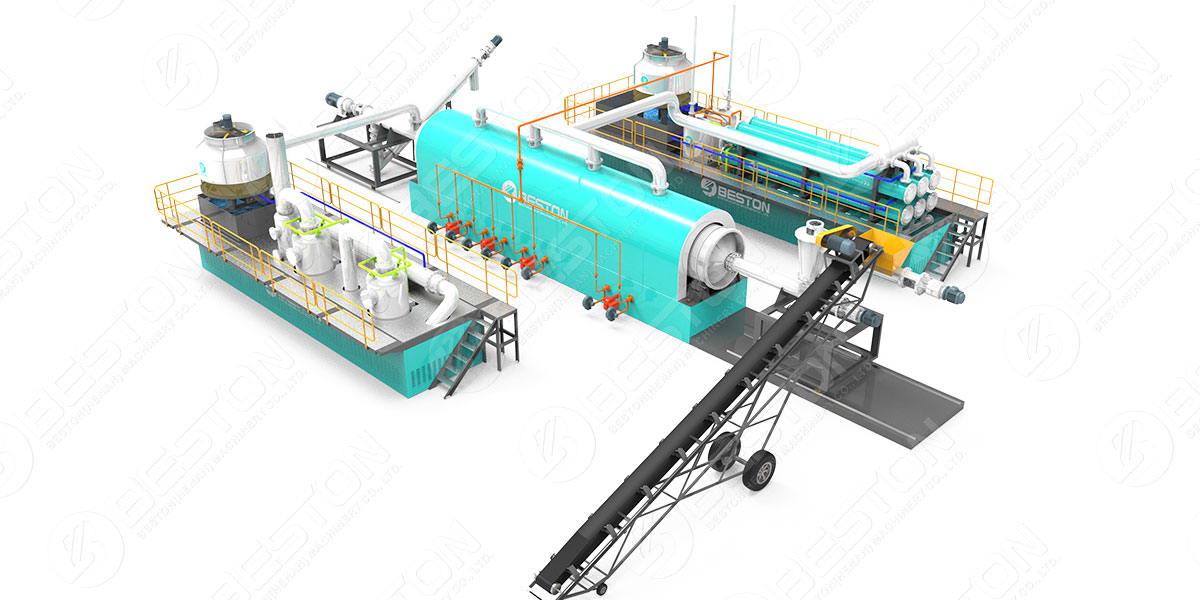

If you do choose to invest in this equipment, you’ll have a number of appealing options to choose from. There are smaller machines that are more portable, and there is heavy equipment that can be used with a range of equipment in addition to sawdust.

Having more choices also means that you’ll be able to find products at different pellet making machine price points. You should connect with a supplier that will be able to give you more information about the types of equipment that are currently on the market.

This Equipment Is Designed To Last

Because a pellet machine will generally be easy to clean, it will be easier for you to keep your equipment in excellent condition as time goes on. You won’t have to worry about the cost of replacing the equipment that you’ve purchased. Instead, you’ll be able to continue to use this equipment.

The machine you buy won’t require extensive upkeep, and you can expect it to last for a very long time. It should hold up well over time even if it is used on a daily basis. You can also buy a sawdust charcoal making machine to recycle sawdust.

Is a sawdust pellet machine worth investing in? In many cases, the answer to that question will be a strong yes. There are many excellent types of equipment on the market, and the pellets that can be produced with this machinery can be used in countless ways.