As sustainable practices become more widespread, various types of biomass-to-charcoal equipment are gaining attention. Among them, biochar machine, charcoal machine, and charcoal briquette machine serve distinct yet interconnected purposes. This article outlines their similarities, differences, and roles within the biomass carbonization process.

What Is a Biochar Machine or Charcoal Machine?

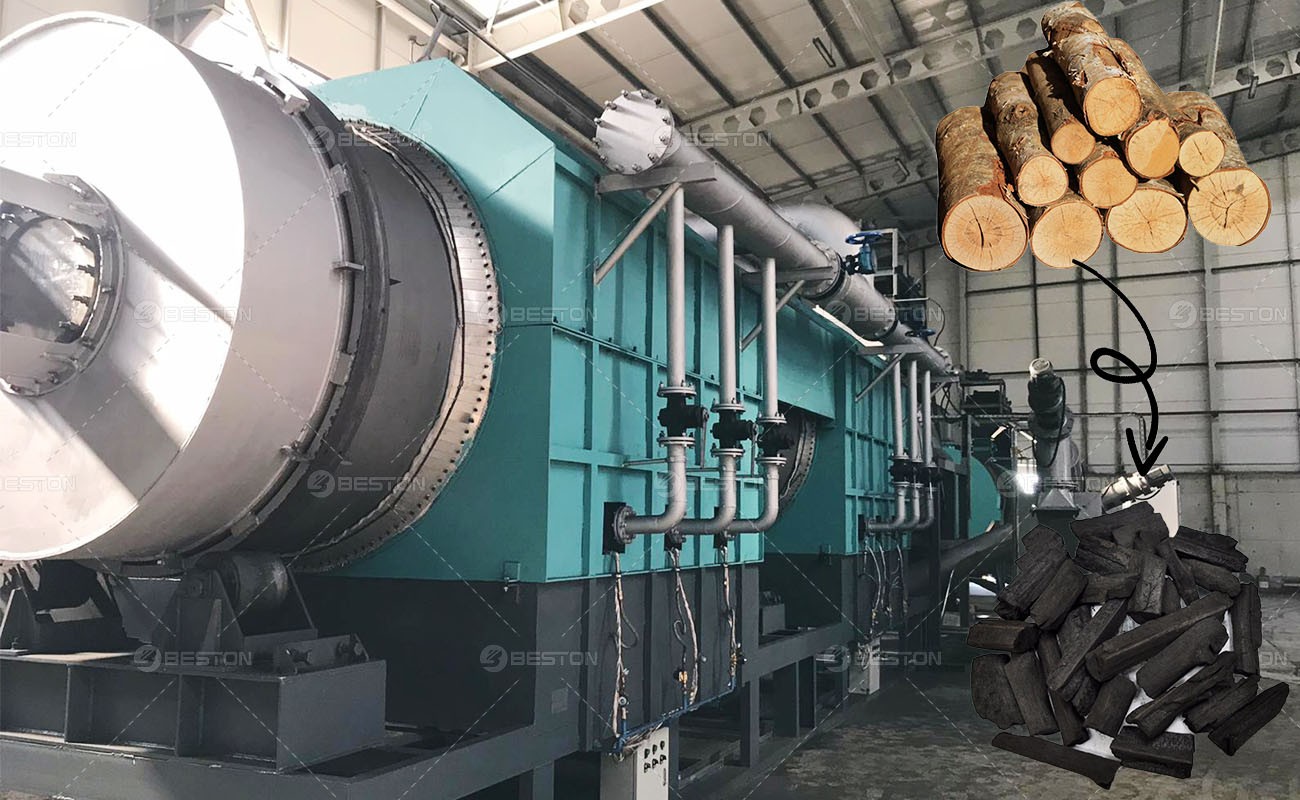

The terms biochar machine and charcoal machine are often used interchangeably. Both refer to equipment that uses pyrolysis technology to convert biomass—such as wood chips, rice husks, coconut shells, or straw—into biochar or charcoal.

These machines operate under an oxygen-limited environment at high temperatures to thermochemically decompose organic material. The result is a carbon-rich, porous material known as biochar (for agricultural use) or charcoal (for fuel or industrial purposes).

Where Does the Charcoal Briquette Machine Fit In?

After the pyrolysis process is complete, the raw charcoal or biochar often comes in irregular chunks or powder form. This is where the charcoal briquette machine comes into play. It compresses fine charcoal powder into uniform briquettes that are easier to transport, store, and market. The briquettes can be shaped into balls, cubes, or cylinders, depending on the mold used.

Unlike biochar machines and charcoal machines, which are responsible for the thermal conversion of biomass, the briquette machine is a post-processing device that enhances usability and commercial value.

Key Differences and Process Flow

- Biochar Machine / Charcoal Machine: Core equipment for biomass pyrolysis. Transforms raw material into charcoal or biochar through heat and low oxygen. Suitable for use in agriculture, metallurgy, and fuel industries.

- Charcoal Briquette Machine: Auxiliary equipment. It does not produce charcoal, but rather shapes it after production. Enhances handling, packaging, and combustion efficiency.

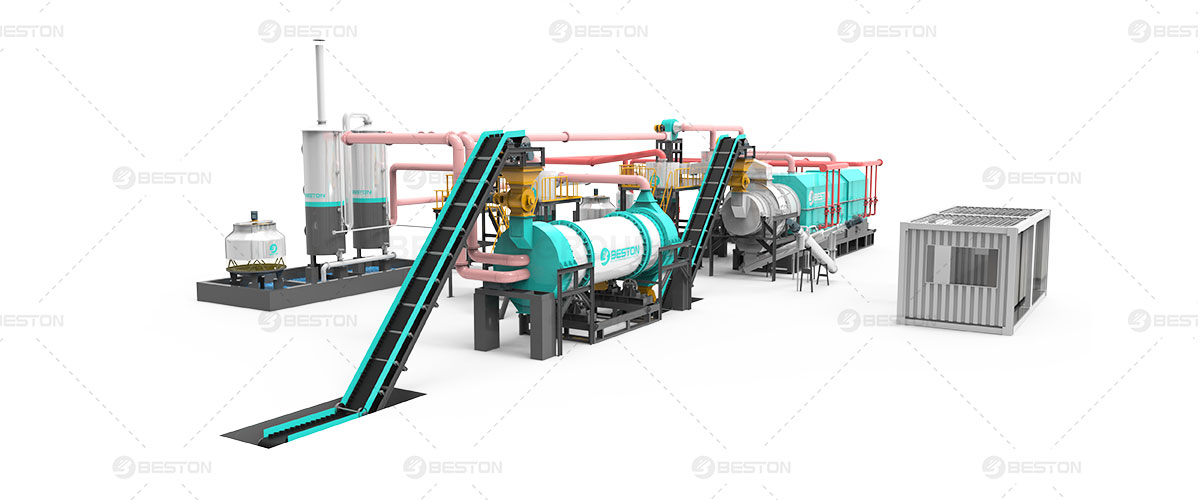

The standard production line looks like this:

- Raw biomass is fed into the biochar/charcoal machine.

- Through pyrolysis, the biomass is carbonized into biochar or charcoal.

- Fine charcoal particles are collected and processed using the briquette machine to produce high-density charcoal briquettes.

Conclusion: Complementary Technologies for Biomass Conversion

Though the biochar machine and charcoal machine are largely synonymous, the charcoal briquette machine serves as a valuable complement in the production chain. Together, they maximize the utility of biomass and offer solutions for waste management, sustainable energy, and soil improvement.

For advanced pyrolysis solutions and integrated systems, Beston Group provides customized equipment lines tailored to commercial and industrial applications.