The wood charcoal industry, deeply rooted in tradition, has evolved into a technologically advanced sector where the dynamics of pricing are intricately tied to a myriad of factors. Understanding the journey from timber to tech is crucial in deciphering the economics behind the pricing of wood charcoal machines.

Introduction

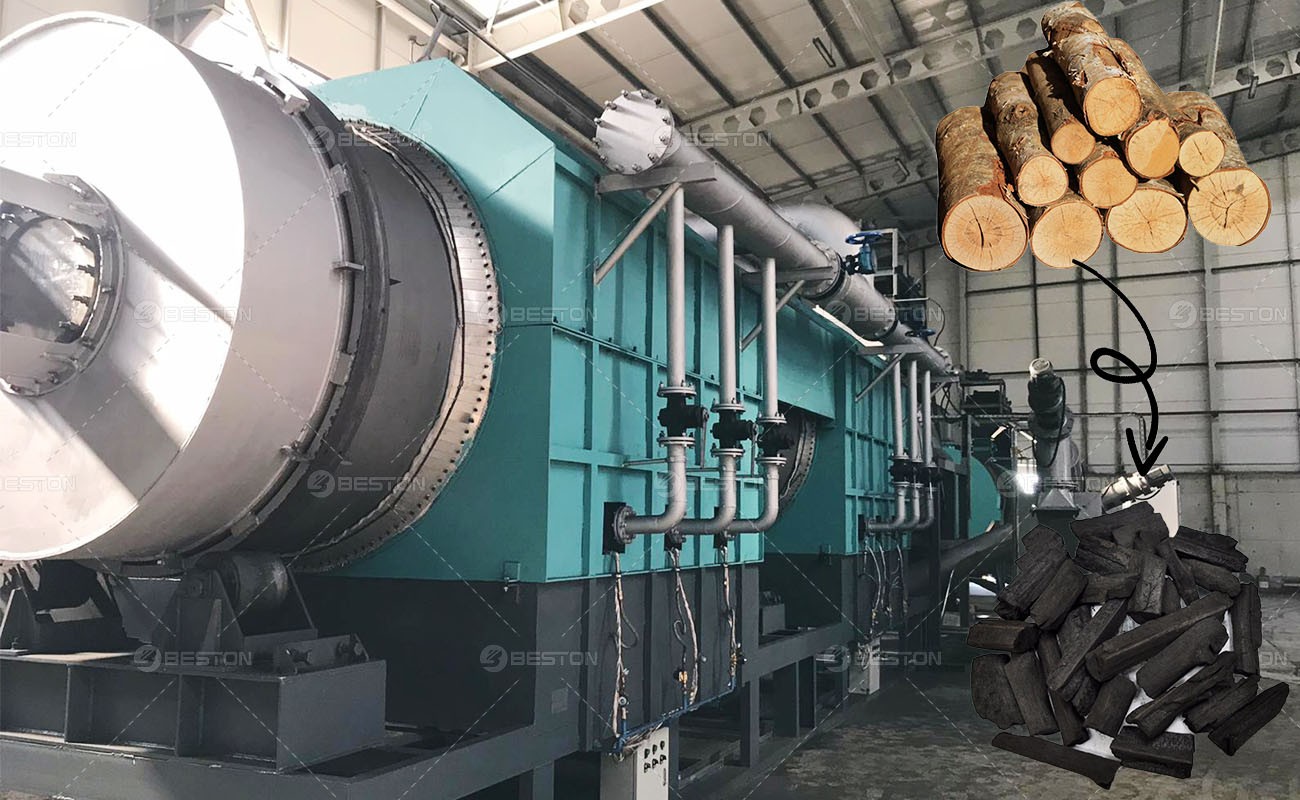

In the vast landscape of the wood charcoal industry, the pivotal role of wood charcoal machines cannot be overstated. These machines serve as the technological backbone of the entire production process, transforming raw timber into the coveted charcoal. This article delves into the multifaceted aspects that contribute to the pricing of wood charcoal machines.

Raw Material Costs

Timber is the Cornerstone

At the heart of wood charcoal production lies the timber, the elemental raw material. The quality of timber directly influences the charcoal machine price. High-quality timber ensures robust and durable machine construction, but it comes at a cost. Exploring the nuances of timber selection sheds light on the intricate relationship between raw material costs and machine pricing.

Market Fluctuations and Raw Material Costs

The wood charcoal industry is susceptible to market fluctuations in timber prices. Variations in timber costs, influenced by factors such as climate, logging regulations, and global demand, ripple through the supply chain, impacting the pricing of charcoal machines. Understanding these fluctuations is essential for manufacturers and consumers alike.

Technological Innovations

Cutting-edge Technologies

The evolution of wood charcoal machines transcends traditional craftsmanship. Modern machines incorporate cutting-edge technologies, from advanced combustion mechanisms to smart features and automation. This section explores how these innovations contribute to the sophistication of charcoal machines and, consequently, their pricing.

Impact of Technological Advancements

The integration of smart features not only enhances user experience but also contributes to the overall efficiency of wood charcoal machines. Automation reduces labor costs and increases production speed, factors that intricately tie into the pricing structure. Unraveling the influence of technological advancements provides a glimpse into the intricate interplay between innovation and cost.

Production Efficiency

Efficiency Metrics

Efficiency metrics serve as the benchmark for evaluating wood charcoal machine performance. This section analyzes key efficiency indicators, such as production speed, energy consumption, and maintenance requirements. Manufacturers navigate the delicate balance between achieving optimal efficiency and managing the costs associated with sophisticated production processes.

Balancing Cost and Efficiency

The quest for enhanced efficiency comes with its own set of challenges. Manufacturers face the delicate task of balancing the upfront costs of incorporating efficient technologies with the long-term benefits they bring. Understanding this delicate equilibrium provides insights into why wood charcoal machines are priced the way they are.

Environmental Considerations

Eco-friendly Features

The modern consumer is increasingly conscious of environmental impact. Wood charcoal machines with eco-friendly features, such as efficient smoke-capturing systems and sustainable sourcing practices, often come with a premium. This section explores the rise of environmentally conscious production and its reflection in the pricing structure of wood charcoal machines.

Certification Standards

Certification standards, such as those for sustainable forestry and emissions, play a pivotal role in influencing machine pricing. Manufacturers adhering to stringent environmental criteria incur additional costs, which are inevitably transferred to the consumer. Unpacking the impact of certification standards unveils the intricate relationship between environmental considerations and pricing.

Market Forces and Demand

Market Demand Dynamics

Wood charcoal machines exist within a dynamic market influenced by factors such as consumer preferences, economic trends, and global demand for charcoal. Analyzing the demand dynamics provides a comprehensive understanding of how market forces shape the pricing landscape for these machines.

Supply Chain Dynamics

The intricate web of suppliers, manufacturers, and distributors in the wood charcoal industry contributes to the complexity of pricing. This section explores the supply chain dynamics and their role in determining the cost structure of wood charcoal machines. Understanding these intricacies provides valuable insights into the market forces influencing pricing. Finding a reliable charcoal making machine manufacturer is the first step to success. They can provide reasonable charcoal making machine prices and considerate after-sales service. Beston Group is recommended to you here, you can visit the website: https://bestonasia.com/ to get in touch.

Regulatory Landscape

Impact of Regulations

The wood charcoal industry operates within a framework of regulations that shape production practices and standards. Compliance with these regulations incurs costs, which, in turn, influence the pricing of charcoal machines. This section examines the impact of existing regulations on machine pricing and anticipates future regulatory trends that may further shape the economic landscape.

Future Regulatory Trends

As environmental and safety concerns continue to gain prominence, the wood charcoal industry is likely to witness evolving regulatory landscapes. Anticipating these trends is crucial for manufacturers and consumers alike, as they signal potential shifts in the pricing dynamics of charcoal maker machines. Understanding the future regulatory framework provides valuable insights for strategic decision-making.

Conclusion

In conclusion, the pricing of wood charcoal machines is a nuanced interplay of raw material costs, technological innovations, production efficiency, environmental considerations, market forces, and the regulatory landscape. Manufacturers and consumers navigating this landscape must be cognizant of these factors to make informed decisions in an industry where tradition meets technology.