A little-known fact about rubber that is recycled is that it can actually produce a type of diesel fuel. It is referred to as bio oil and it is used for many different products. It is very popular with women that are pregnant. They can rub that on their bellies to prevent stretch marks. It is most popular, however, as an alternative to diesel fuel. The consistency and proficiency of these newer machines makes it possible for companies to process millions of rubber containers every month, helping them to generate a substantial profit. Rubber to diesel machine design with pyrolysis capabilities is exactly what you need in order to start earning more money with your existing business, or to create a completely new business as long as you have an ample source of rubber to consistently run through this rubber pyrolysis machine.

Rubber to Diesel Machine Design

What Pyrolysis Is Able To Do To Rubber

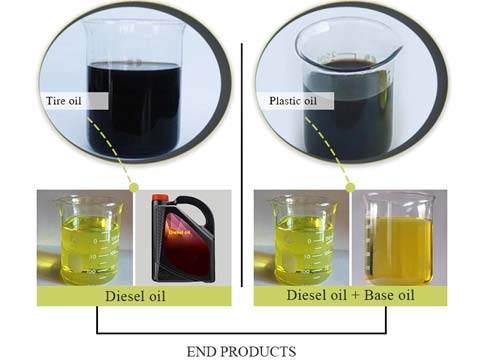

there is a chemical process that actually can occur to rubber when it is heated up to a certain temperature. It is a material breakdown at the molecular level. It separates into different components such as the bio oil and the biochar. All of this is possible because there is no oxygen involved in the process. If oxygen were introduced, it would burn, and the possibility of extracting those different components would not happen. Instead, these companies are able to create these pyrolysis machines specifically for companies that are processing rubber tires, and rubber bottles, helping them to clean up the environment and also make a good amount of money.

Why Rubber To Diesel Conversions Are So Popular

Part of the reason for this popularity is due to the fact that the cost of diesel fuel is relatively high. Although gas prices have been dropping, it still more cost-effective to produce this type of bio oil using rubber that you might be able to get for free. Essentially, you are paying for the equipment that you run and the cost of running it. However, the cost of the fuel will be free due to the plastic you have available. Even if you are paying a small amount for the plastic bottles that you are feeding into the system, it’s still going to be a significant discount over the cost of diesel from plastic waste.

How Long before You Make Your Money Back?

A concern that many investors have when going into this type of businesses they wonder how long it will take before they are able to get their money back. It is a profitable business venture, more so than ever before simply because it is a much more efficient rubber to diesel production line that these machines used today. In most cases, you can start to see profitable returns and just a year or two, perhaps longer depending upon the size of your operation. In the end, you are doing a great service for the environment, and profiting at the same time, making this a win-win situation regardless of how you look at it. See the project in UK https://bestonmachinery.com/pyrolysis-plant/uk/.

If you do have an ample supply of rubber that you can use to feed into one of these machines, you will definitely benefit from this type of business. If all you want to do is produce diesel fuel for the trucks and cars that you run for your business, this is also a good idea to go in this direction. Waste rubber to diesel machine design today is just absolutely fantastic with regard to return on investment. You won’t have to worry about making your money back with the quality machines that you can get from companies in the Orient which only produce the best. Here is Beston Pyrolysis which has details of rubber to diesel plant design for you to see.