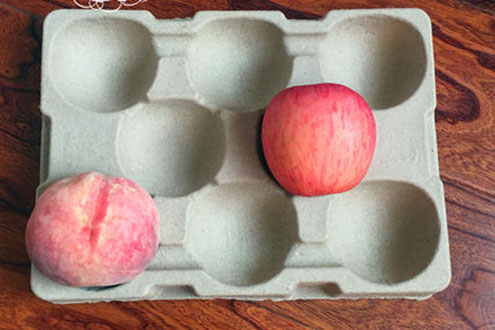

With a modern pulp moulding machine, you can make biodegradable egg trays and egg cartons from paper-based waste materials. Paper pulp molded trays are a sought-after type of packaging in the egg industry as they prevent eggs from breaking during transportation and make them easier to store. While the main function of basic recyclable egg trays is to provide cushioning that reduces breakages, you can add various additives to the pulp mix which make the trays produced more water-resistant. It’s also possible to add a coloring agent to the pulp mix to make different colored cartons and trays for different types of eggs. In the UK, for example, many duck eggs are packaged in blue or white cartons to distinguish them from chicken eggs that are typically packaged in brown or yellowish egg boxes. The pulp moulding machine is used to make various paper trays.

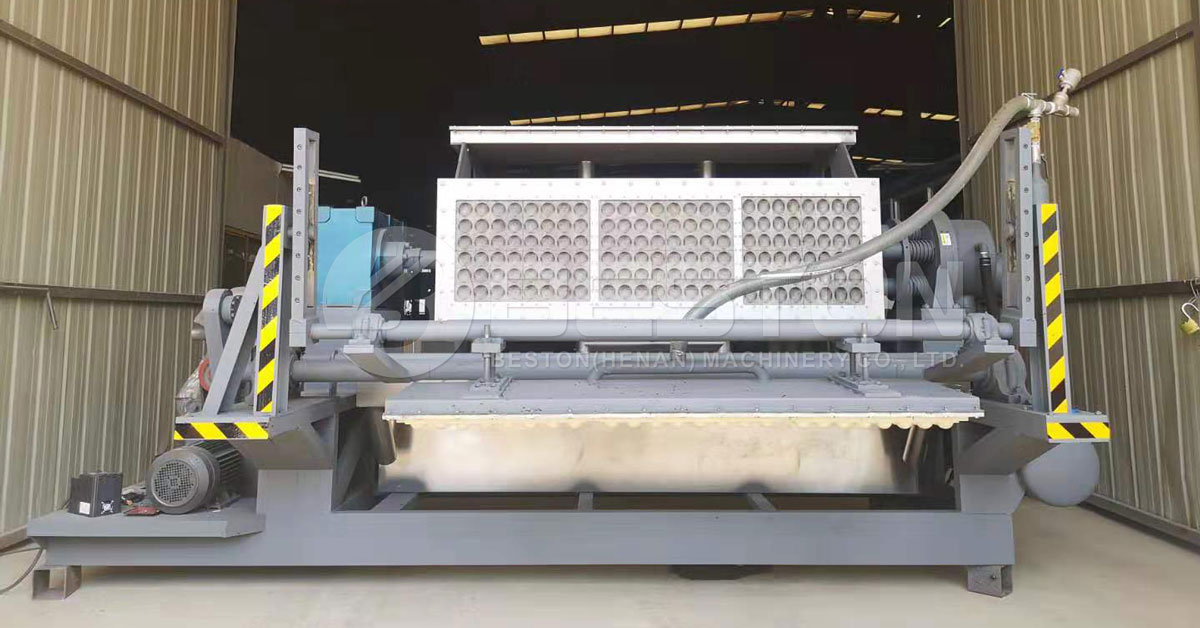

2500pcs Pulp Moulding Machine

If you are looking for a profitable business opportunity, setting up an egg tray manufacturing plant is certainly something to consider. Many people that invest in egg tray making machines enjoy very fast returns on their investments. Some machines for sale can output over 6000 units per hour and are able to run 24/7. Click here to know more: https://eggtraymakingmachine.net/egg-tray-production-line/.

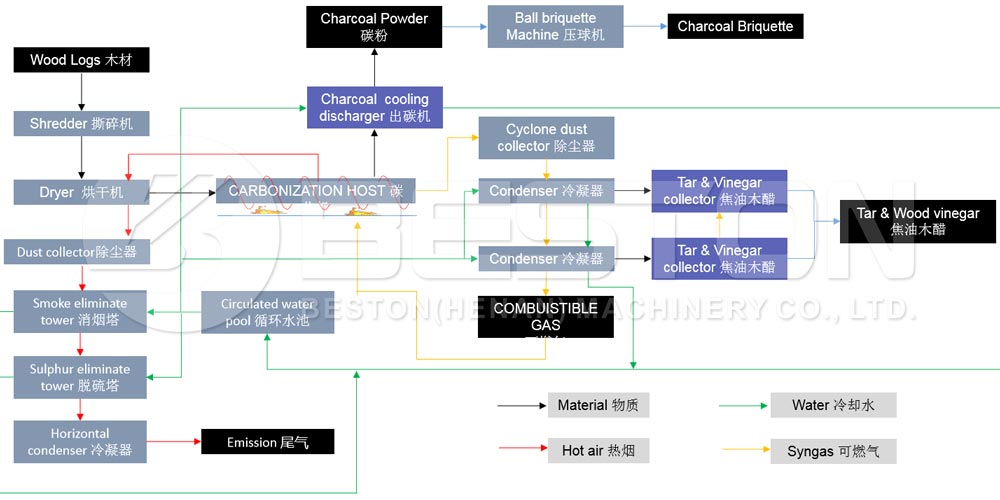

While plastic egg packaging is widely used, paper pulp-based trays are much cheaper to make and more eco-friendly. The raw materials you need access to start an egg tray manufacturing business are basically just water and waste paper, such as old books, newspapers, used paper bags, etc. In some regions, paper recycling waste can be purchased very cheaply and some municipal waste processing facilities will even pay outside companies to take the waste off their hands. Other raw materials you may need to begin production include additives and fuel to power the egg tray making machinery. Get competitive manual egg tray making machine price here.

Egg Tray Making Machine to India

Pulp Moulding Machine Manufacturers

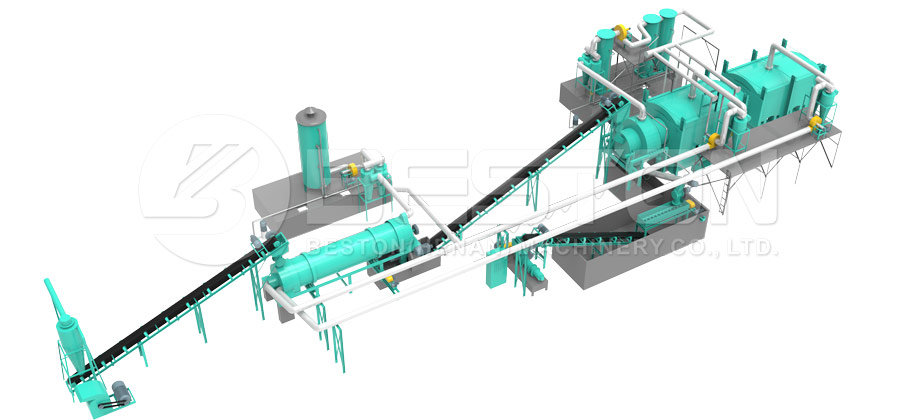

Some of the globe’s biggest pulp moulding machine manufacturers export their products to customers located in dozens of different countries. One manufacturer recently sold automatic egg tray making machines to businesses in Egypt, Russia, India, and the Philippines. Some perks of top-rated suppliers include speedy shipments, extended machine service warranties, and 24/7 technical support. Such suppliers also provide customizable machine configurations that match any unique specifications requested by customers.

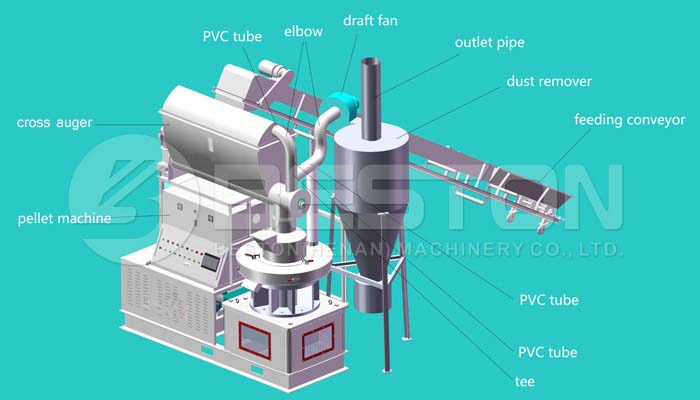

Egg Tray Pulp Moulding Machine Specs

Technical specifications of paper pulp moulding machines vary greatly between different models. Some of the specs buyers need to pay attention to are: output capacity, fuel consumption, working method, number of molds, dimensions, power requirements, and drying system type. For egg tray manufacturing businesses in countries where labor costs are high, fully automatic machines are likely to be the best choice as they can output over 100,000 pieces each week with a very scaled back workforce. Additionally, businesses located in countries with cold, wet climates need to ensure they opt for a machine with an integrated automatic drying system. Fortunately, there are dozens of different models available to suit the unique requirements of any and all egg tray making businesses. More information on the blog: https://bestoncompany-17.webself.net/.