Once you decide to buy a mini pyrolysis machine, it is now time to do your due diligence. It takes time and effort to find high-quality machines. If you choose the wrong machine, it can cost you more money. It is, therefore, essential to set your budget, compare multiple mini pyrolysis machines, and choose a higher quality mini skid mounted pyrolysis plant.

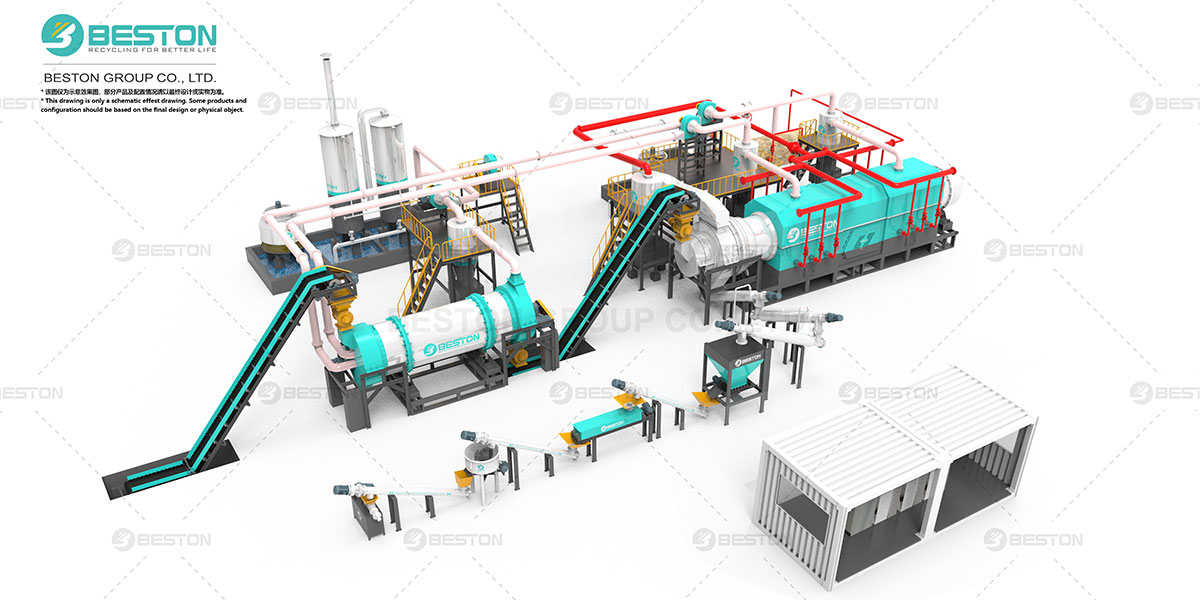

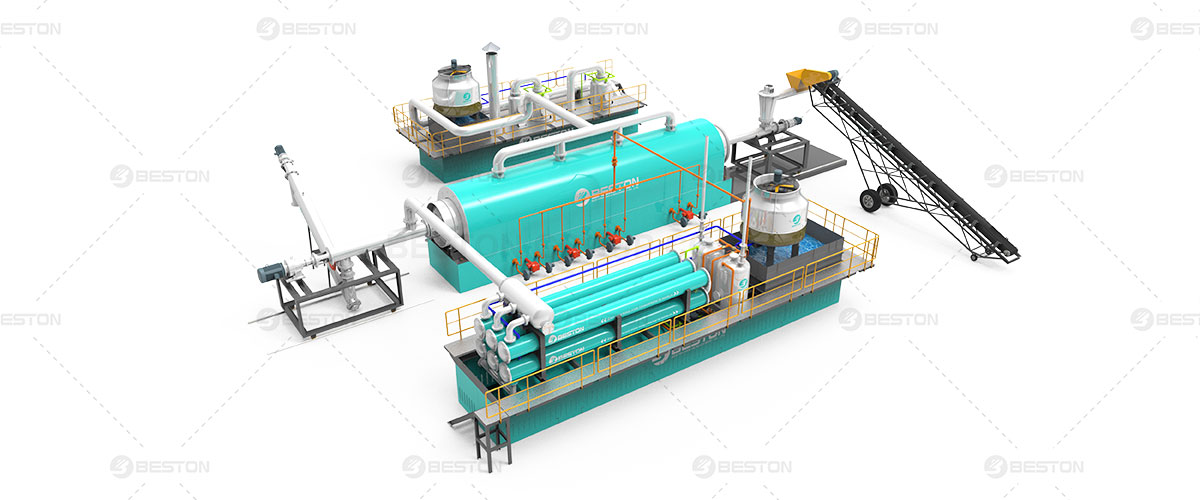

Mini Waste Pyrolysis Plant Shipped to the Philippines

Here are 6 Tips to Buy a Mini Pyrolysis Machine:

1. Buy From Reputable Sources Only

It is better to buy mini pyrolysis machines from reputable sources. Reputable sources sell high-quality machines at affordable prices. And they have great customer service.

If you buy a machine from a reputable source, it can serve you for several years without any complaints. It is, however, necessary to check the condition of the machine before buying. See the pyrolysis reactor manufacturers.

2. Check The Warranty

Almost all machines come with a warranty. The company, manufacturer, or dealer provides a warranty with their mini pyrolysis machines. The warranty is a good thing for you.

The warranty can give you peace of mind. If your machine breaks down, the company can repair the machine for free. It is, therefore, crucial to compare the warranties before buying a machine.

Mini Skid-mounted Pyrolysis Plant

3. Buy Branded Machine

It is best to buy a branded mini pyrolysis machine. Do not, however, rely too much on the brand. It is beneficial to buy branded machines since they can last longer. The top brands make high-quality machines.

It is important to check the machine to ensure it is in good working condition. It is easier to deal with the top brands. They can even help you repair and maintain your machine.

4. Consider the Maintenance Costs of the Machine

You should research and learn more about the features, model, and brand of the mini pyrolysis machine. You want to know the cost of maintaining the machine. See this case – tyre recycling in Nigeria.

It is expensive to maintain some machines. If you have a small business, you might not afford to use these machines. Make sure you can afford to maintain the machine before buying.

Proper maintenance can increase the lifespan of the machine.

5. Focus On Quality Of The Machine

Mini pyrolysis machines come in all types of qualities and brands. It is much better to spend your hard-earned money on a higher-quality machine.

Do not buy the cheapest machines. They are expensive to maintain. They can, therefore, cost you more money to use them. If you want to save money, go for a high-quality machine.

6. Set Your Budget

Set your budget before you buy a mini pyrolysis machine. Once you set your budget, you can now compare the features of the machines within your budget. Choose a machine with the features you are looking for.

It is cheap to buy used machines. If you are good at negotiation, you can buy a used machine at half the price. It is, however, better to check the condition of the used machine before buying it. Find more machines on this web – Bestonmachinery.com.

It is best to spend money on higher quality machines. It is easy to find their spare parts. They are cheap to maintain. And they can last longer.

Conclusion

It is essential to do your due diligence before buying a mini pyrolysis plant. It is better to buy the machine from a reputable source. If you want to buy a used machine, you must inspect it to ensure it is still in good working condition.