In recent years, the management of tyre waste has become a critical environmental concern. Traditional disposal methods, such as landfilling or incineration, contribute to environmental degradation by releasing harmful emissions and occupying valuable land. One of the most innovative and sustainable solutions to this problem is the deployment of a tire pyrolysis plant. This technology offers a pathway to convert waste tyres into valuable resources while mitigating the environmental impact associated with their disposal.

The Mechanism Behind Tire Pyrolysis

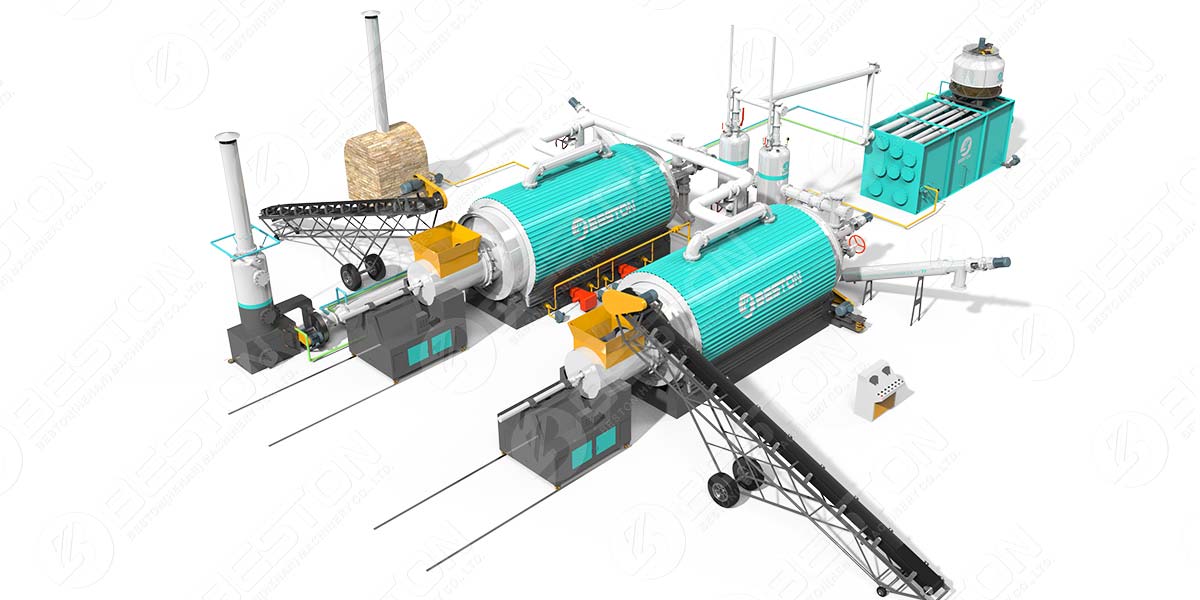

A tire pyrolysis plant operates through a process known as pyrolysis, which involves heating waste tyres in the absence of oxygen. This thermal decomposition breaks down the rubber into several useful by-products: oil, gas, and carbon black. The pyrolysis machinery ensures that the process is controlled and efficient, allowing for the recovery of these products at high yields.

In the case of a continuous tyre pyrolysis plant, the waste tyres are continuously fed into the system, ensuring uninterrupted operation. This setup significantly enhances productivity compared to batch-processing models, where tyres are processed in discrete cycles. The continuous feed system reduces downtime and increases overall throughput, making it an ideal solution for large-scale operations.

Environmental Benefits of Tire Pyrolysis

The environmental advantages of using a continuous tyre pyrolysis plant for tyre waste management are manifold. First, it reduces the reliance on traditional disposal methods, which often lead to the accumulation of non-biodegradable waste in landfills. By converting waste tyres into useful products, the pyrolysis process significantly lowers the environmental burden.

Second, the by-products of the pyrolysis process, such as tire-derived oil and gas, can be utilized as energy sources. Tire-derived oil can be refined and used as an alternative fuel in various industries, including cement production, electricity generation, and as a diesel substitute. The gas produced during pyrolysis can be used to fuel the plant itself, creating a self-sustaining cycle that reduces the need for external energy inputs.

Furthermore, the carbon black produced in the process can be used in manufacturing new tyres or as a filler in various industrial applications. This closed-loop system not only recycles valuable materials but also helps reduce the need for raw materials, supporting circular economy principles.

The Role of Continuous Pyrolysis Plants in Scaling Operations

One of the key advantages of continuous pyrolysis plants is their scalability. These plants are designed to handle large volumes of waste tyres efficiently, making them suitable for both small and large-scale operations. With the continuous input of tyres, the plant can process thousands of tonnes of waste per year, contributing significantly to waste reduction on a global scale.

Moreover, the advanced control systems embedded in the continuous pyrolysis plant ensure consistent processing, which is essential for maintaining high-quality by-products. This operational consistency enhances the profitability of tyre recycling projects, as businesses can rely on a steady supply of high-value materials.

Conclusion

Tire pyrolysis plants, particularly continuous models, play an essential role in sustainable tyre waste management. By converting waste tyres into valuable resources, these systems help reduce environmental pollution, conserve natural resources, and contribute to the circular economy. As the global demand for sustainable waste management solutions increases, the continued development and implementation of pyrolysis machinery will be crucial in addressing the growing challenge of tyre waste disposal.