If you’re in the market for an egg crate making machine, you’ll find that you have many different options. When exploring your choices, you’ll want to focus on finding machinery that is highly dependable. Here’s how you can invest in equipment that you can depend on.

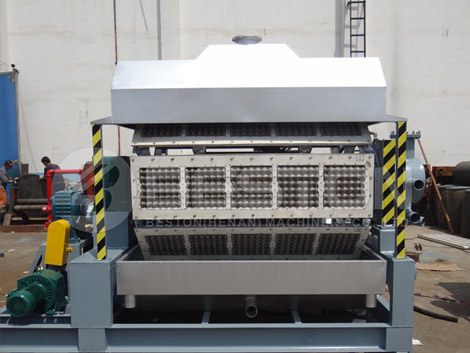

Egg Crate Making Machine

Buy From A Reliable Vendor

When you’re shopping for egg tray equipment like this, it’s always essential to shop with a vendor that you trust. You should make sure you buy your machine from a vendor that has a strong selection of products and a positive reputation.

You don’t necessarily need to limit yourself to vendors that are located in your region. There are many reputable international vendors that sell pulp molding machine. Take the time to identify different vendors that sell the kinds of products you want. Compare your options and make an informed purchase.

Know What You Are Looking For

Because there are so many types of egg crate machines on the market, it’s important to identify what you want from the equipment you are buying. Are you interested in a fully automatic machine, or would you prefer a machine that operates manually? Do you want a machine that makes egg trays from paper or another material?

You’ll also want to set a budget for your purchase. If you know what you’re comfortable spending, you’ll be able to focus your attention on options that are in that price range. You can check the link here to see what you should know before starting an egg tray manufacturing business: https://wasterecyclingplant.com/egg-tray-manufacturing-project-report-india/.

Purchase A Product That’s Under Warranty

If you have an issue with your machinery at some point down the line, you’ll want to make sure you have an easy and effective way to resolve that problem. If possible, you’ll want to see if the machinery you’re buying comes with some sort of warranty.

Don’t just check to see if there is a warranty. You should also find out what sort of coverage the warranty provides. Not all warranties are equal, and you should try to purchase a machine that provides a higher level of coverage if that is possible. Look closely at warranties to see if they will give you the coverage you need.

Stick With Brands That You Trust

You should aim to buy products that are made by reputable pulp molding machine manufacturers. Certain manufacturers, such as Beston Machinery, have a reputation for excellence. The brand name can tell you a great deal about a product, which is why you should always buy from a dependable brand if you can.

Egg Tray Machine in Dominica

If you don’t know much about the manufacturers that make these machines, now is an excellent time for you to research these brands. Find brands that have been producing molding machinery for years. If you buy from a brand like this, you’ll know exactly what you’re getting.

If you specifically seek out these things, you’ll be able to find a reliable egg crate making machine for sale. More importantly, you’ll be able to get the equipment you want without spending a fortune. You’ll be able to produce plenty of egg cartons with minimal issues.