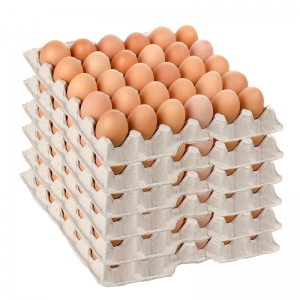

Selling egg trays is a prospective business idea, especially with the high demand for egg trays in many countries. But the first thing you need to start your business is an egg tray-making machine. This machine uses water and waste paper to make egg trays. But before you buy the machine, you should know about its parts. Here are the essential parts of an egg tray making machine for sale that help in making high-quality egg trays:

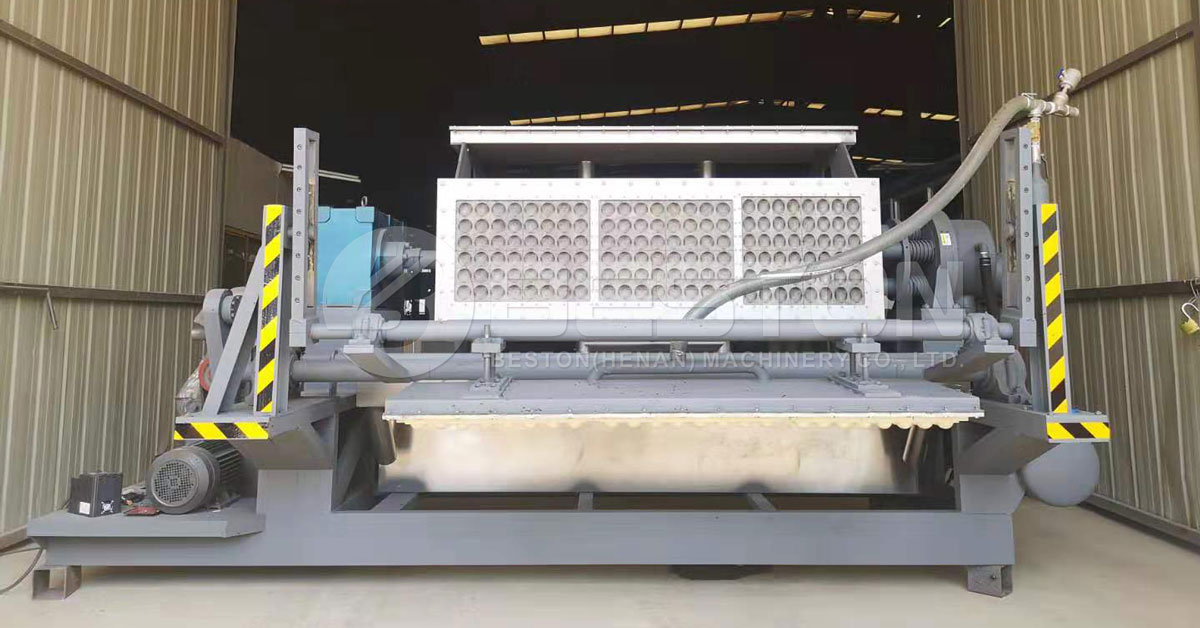

Egg Tray Making Machine Sold to the Philippines

1. Pulper

The pulper has two functions: shred the waste paper and make a paste using water. You need to take three portions of waste paper and mix it with one portion of water. For example, if you take 3 kg of waste paper, you should put 1 kg of water into the pulper. The pulper works like a mortar and pestle. It keeps mashing the paper and water to make a thick paste. The pulper ensures that there are no lumps in the mixture. This helps to avoid wastage while molding the paper trays.

2. Vacuum Pump and Molding Machine

These two parts work simultaneously. First, the pulper sends the mashed paper paste into the pulp pool. Next, the vacuum pump sends the pulp into the molding machine, where the pulp gets molded into the shape you want. This is where you need to decide which type of mold you want to use. You can make 30-egg trays, 12-egg trays, or even 4-egg trays. If you don’t get the desired mold while purchasing the machine, you can buy one separately. The egg tray machine Philippines price depends on the model you choose. You can search for some cases in the Philippines.

3. Drying System

It’s time to dry the trays once they take shape. This is one of the most crucial parts of making egg trays. According to experts, the better the drying system, the lower the wastage. Suppose you are using a manual machine that has a natural drying line. It will have more wastage because the weather conditions may not be suitable to dry the trays quickly.

Instead, it’s best to use a nursery tray machine that comes with a brick drying line or metal drying line system. These two can dry egg trays fast and reduce wastage. The advantage of using a metal drying line system is you don’t need to use wood or coal as fuel. Sometimes, they may affect the quality of your egg trays if you don’t figure out when to put the trays in the drying line.

Egg Tray Making Machine Shipped to Egypt

4. Stacking and Packing

This is an additional part of an egg tray making machinery. You may need to buy it separately. It’s wise to invest in the packing machine when you buy the egg tray making machine because it stacks and packs your egg trays within a few minutes. Egg tray making machines can make 2000 to 6000 trays in an hour. Imagine the amount of time it will take to dry so many trays naturally and then start packing. Instead, use a machine that has an automatic drying line, along with stacking and packing part. Visit this respected egg tray machine manufacturer.

Making 6000 egg trays in an hour may be enough to meet the demands of your customers. Keep an eye on these parts when you buy the machine to make the most number of trays.