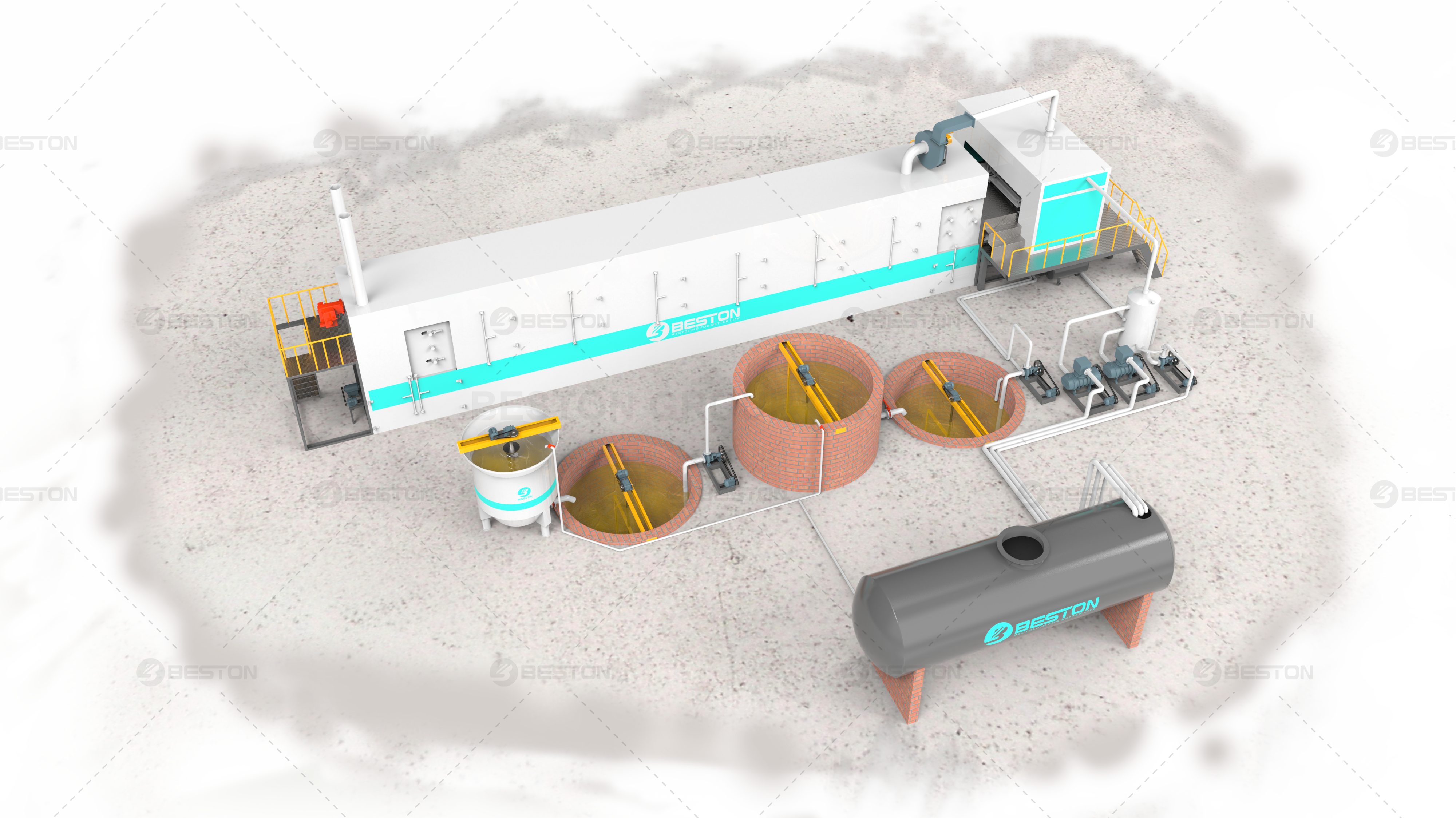

Starting an egg tray manufacturing business can be a profitable venture with high demand for egg packaging solutions. However, before you start the business, you need to invest in an egg tray making machine. The egg tray making machine cost can be a significant factor in the success of your business, as it can determine your profit margins.

Factors Affecting Egg Tray Making Machine Price

Several factors affect the price of an egg tray making machine. Here are some of the most critical factors:

- Production capacity: The higher the production capacity of the machine, the more expensive it will be.

- Automation level: Fully automated machines are more expensive than semi-automated or manual machines.

- Brand reputation: Well-established brands with a good reputation in the market tend to charge more for their machines.

- Material used: The type and quality of materials used in the construction of the machine can affect pulp molding machine price.

- Warranty and after-sales support: Machines with longer warranty periods and better after-sales support tend to be more expensive.

Price Range of Egg Tray Making Machines

The price of an egg tray making machine varies depending on the factors mentioned above. However, the price range for these machines is typically from $10,500. Manual machines are the most affordable. Semi-automatic and fully automated machines maybe cost more: https://pulpmouldingmachines.com/molded-pulp-packaging-machinery/.

Where to Find the Best Deals

There are several places to find the best deals on egg tray making machines. Here are some options:

- Online marketplaces: Websites like Alibaba and Made-in-China offer a wide variety of egg tray making machines at competitive prices.

- Local manufacturers: You can also find local manufacturers who can provide customized machines at affordable prices.

- Trade shows: Attending trade shows and exhibitions can give you the opportunity to meet with manufacturers and suppliers and negotiate a good deal.

In conclusion, the industrial packaging machine price is a crucial factor to consider when starting an egg tray manufacturing business. Understanding the factors affecting the price and where to find the best deals can help you make an informed decision and invest in the right machine for your business.