In the pursuit of sustainable agricultural practices, the effective management of biomass holds paramount importance. Rice husk, corn stalk, jute stick, and straw are among the abundant residues generated in agricultural activities worldwide. However, these byproducts often pose significant disposal challenges and environmental concerns.

The Role of Pyrolysis in Waste Biomass Recycling

Pyrolysis emerges as a promising solution for the conversion of agricultural waste into valuable resources. This thermochemical process involves the decomposition of organic materials at elevated temperatures in the absence of oxygen. Through pyrolysis, biomass can be transformed into biochar, bio-oil, and syngas, offering diverse applications in energy production, soil amendment, and industrial processes.

Rice Husk: A Potential Feedstock for Pyrolysis

Rice husk, a byproduct of rice milling, is rich in lignocellulosic material and possesses high calorific value. When subjected to rice husk charcoal making machine, rice husk undergoes thermal degradation, yielding biochar with porous structure suitable for soil conditioning and carbon sequestration. Additionally, the produced bio-oil and syngas can serve as renewable fuels, contributing to the reduction of fossil fuel dependency.

Corn Stalk and Jute Stick: Alternative Biomass Sources

Corn stalks and jute sticks are abundant agricultural residues generated from corn and jute cultivation, respectively. These lignocellulosic materials exhibit favorable characteristics for pyrolysis, including high cellulose and hemicellulose content. Through controlled heating in pyrolysis reactors, corn stalks and jute sticks can be converted into biochar for soil enhancement and bio-oil for energy generation, thereby valorizing otherwise underutilized biomass resources.

Straw: Addressing Waste Management Challenges

Straw, the stalks of cereal crops such as wheat, barley, and oats, represents a significant agricultural residue worldwide. Often left unutilized or burned in open fields, straw disposal contributes to air pollution and soil degradation. However, through straw charcoal making machine, straw can be transformed into biochar, a stable carbon-rich material beneficial for soil health and carbon sequestration. Moreover, the bio-oil derived from straw pyrolysis can serve as a renewable energy source, offering an eco-friendly alternative to fossil fuels.

Implementation of Biomass Pyrolysis Plants

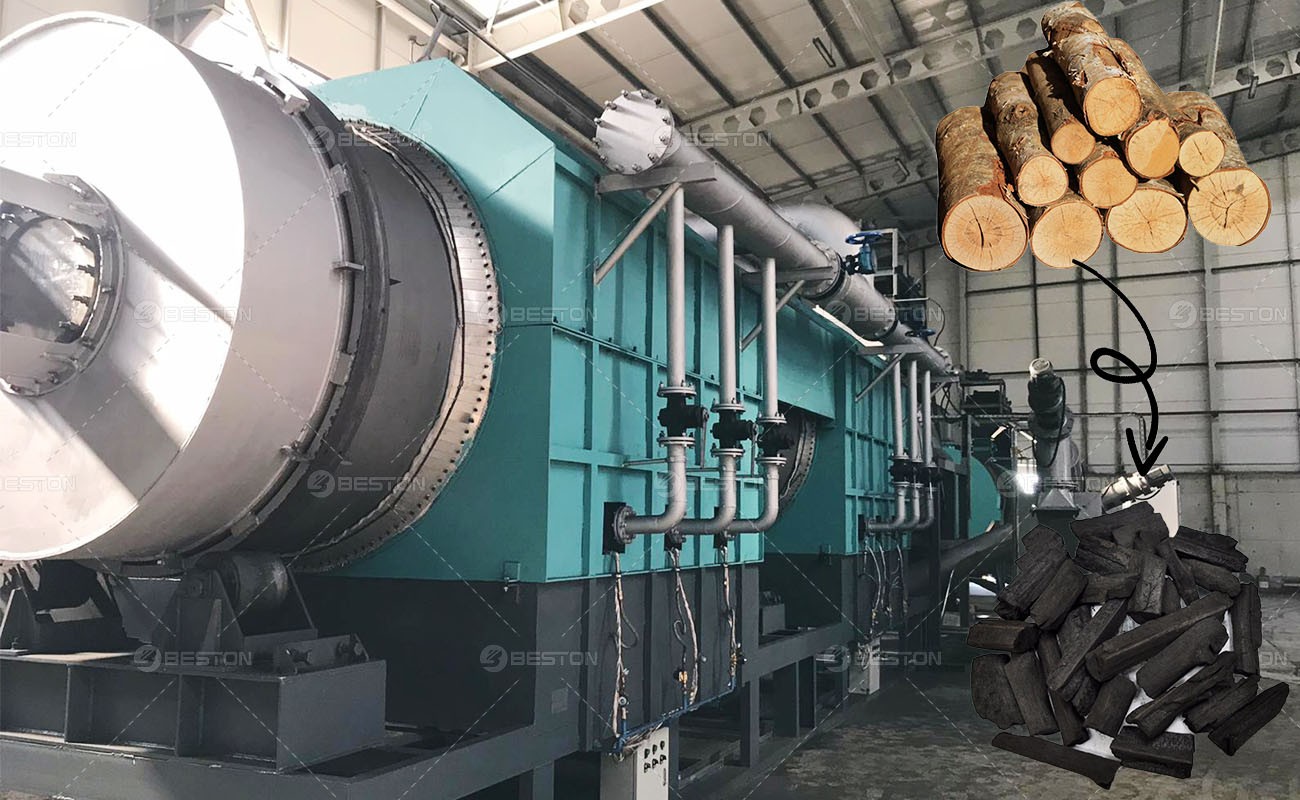

The establishment of biomass pyrolysis plant is integral to the successful implementation of agricultural waste recycling through pyrolysis. These facilities are equipped with advanced technologies and specialized equipment to optimize the pyrolysis process and maximize resource recovery.

Operational Process:

- Feedstock Preparation: Rice husks, corn stalks, jute sticks, and straw are collected and processed to remove impurities and achieve uniform particle size, facilitating efficient feeding into the pyrolysis reactor.

- Pyrolysis Reactor: The prepared biomass feedstock is introduced into the pyrolysis reactor, where it undergoes thermal decomposition at controlled temperatures typically ranging from 300 to 800°C.

- Product Recovery: The pyrolysis process yields three main products: biochar, bio-oil, and syngas. These products are separated and collected using specialized systems for subsequent utilization in various applications.

- Residue Management: Residual ash generated during pyrolysis, along with any unconverted char, is managed through proper disposal or utilization, ensuring minimal environmental impact.

Environmental Benefits of Pyrolysis-Based Biomass Recycling

The adoption of pyrolysis-based biomass recycling offers several environmental advantages, including:

- Greenhouse Gas Mitigation: By converting agricultural waste into biochar and bio-oil, pyrolysis helps mitigate greenhouse gas emissions by sequestering carbon in stable soil carbon pools and displacing fossil fuel consumption.

- Soil Improvement: The application of biochar derived from pyrolysis enhances soil fertility, water retention, and nutrient availability, thereby promoting sustainable agricultural practices and mitigating soil degradation.

- Renewable Energy Production: The bio-oil and syngas produced during pyrolysis can serve as renewable energy sources, reducing reliance on non-renewable fossil fuels and contributing to the transition towards a low-carbon economy. For more information on agricultural waste biomass recycling solutions, please contact Beston Company.

Conclusion

In conclusion, pyrolysis stands out as a viable and sustainable solution for recycling agricultural waste biomass, including rice husk, corn stalk, jute stick, and straw. Through controlled thermal decomposition, these abundant residues can be converted into valuable resources such as biochar and bio-oil, offering environmental, agricultural, and energy-related benefits. The establishment of biomass pyrolysis plants further facilitates the efficient implementation of this technology, paving the way for a more circular and resource-efficient agricultural sector.