Continuous tire pyrolysis plants represent a compelling opportunity for investors focused on sustainable waste-to-energy solutions. These advanced systems convert waste tires into valuable byproducts, such as pyrolysis oil, carbon black, and gas, providing a viable answer to global tire waste issues. Given the growing demand for alternative fuel sources and the pressure to manage waste sustainably, understanding the investment potential in continuous tire pyrolysis is essential.

Market Demand for Pyrolysis Products

The financial prospects of investing in a continuous waste tire pyrolysis plant are closely linked to the demand for its byproducts. Pyrolysis oil, a primary output, has garnered significant interest as an alternative fuel, particularly in industries where fuel cost and environmental compliance are key concerns. This oil can be refined into various grades and is used in industrial heating applications and, in some cases, as a blending agent in transport fuels.

Carbon black, another byproduct, has applications across industries, from rubber manufacturing to coatings. Recycled carbon black is gaining acceptance due to its lower cost compared to virgin carbon black and its reduced environmental impact. The gas produced during pyrolysis can also be leveraged internally to power the pyrolysis plant, cutting down operational costs by providing an internal energy source.

Advantages of Continuous Pyrolysis Technology

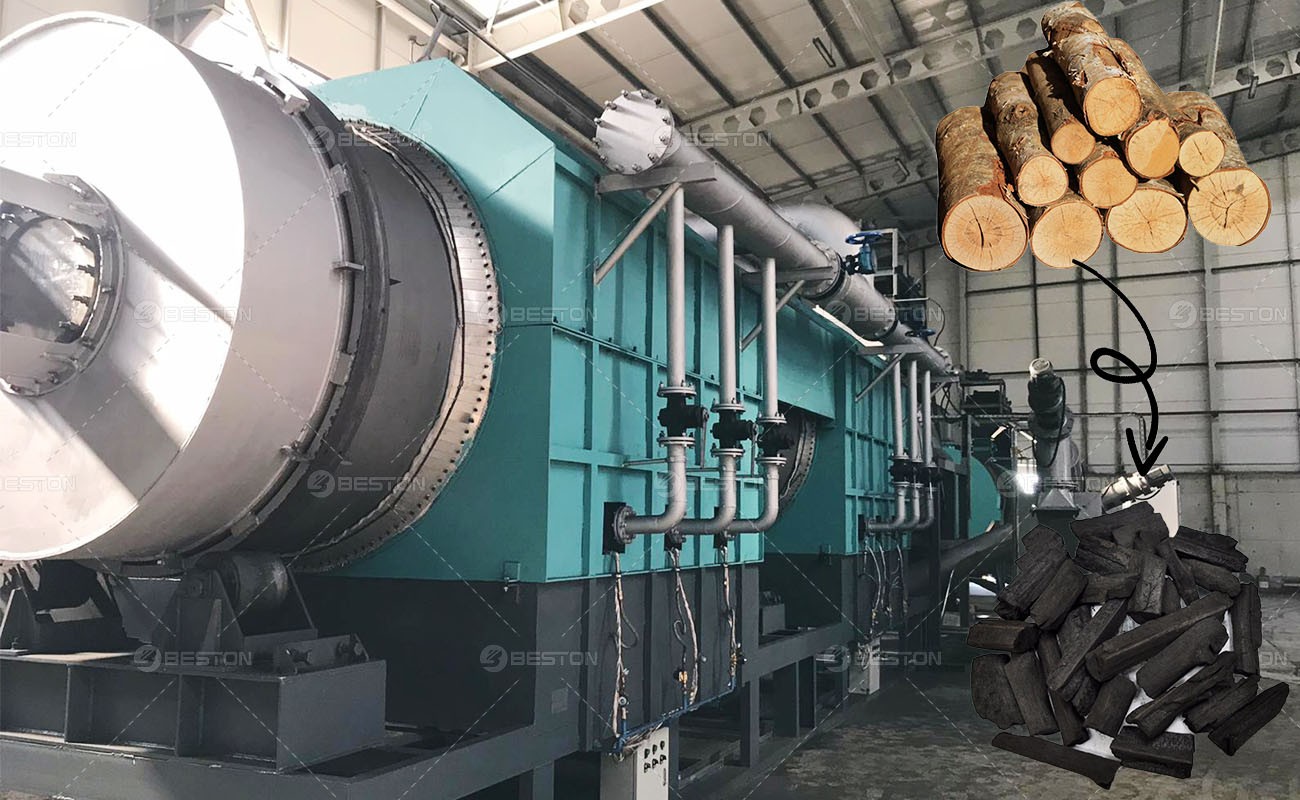

Unlike batch systems, continuous tire pyrolysis plants offer uninterrupted feedstock processing, boosting output and enhancing efficiency. Continuous plant has automated feeding and discharging systems that allow the process to run around the clock. This increased efficiency not only maximizes throughput but also optimizes resource use, making these plants highly attractive from an investment perspective.

Furthermore, continuous systems typically feature improved energy recovery mechanisms, which allow for self-sustaining operation. By using the gas byproduct for energy, these systems reduce reliance on external power sources. This feature lowers operational expenses over time, improving the plant’s profitability.

Initial Investment and Operating Costs

Investing in a continuous tire pyrolysis plant requires substantial capital, with costs influenced by factors such as plant size, technology, and capacity. While initial tire pyrolysis plant cost and equipment expenses are higher compared to batch systems, the operational efficiencies achieved often justify these upfront costs. A well-chosen continuous pyrolysis plant can offer a strong return on investment, particularly as rising waste management challenges create more market demand for such facilities.

Operating costs include expenditures on labor, maintenance, utilities, and raw materials. However, continuous plants typically have lower labor requirements due to their automation features, which further reduces costs. Maintenance costs are also minimized since automated systems experience less wear and tear, adding to the overall financial viability of continuous pyrolysis systems.

Regulatory Incentives and Environmental Compliance

Government regulations and incentives also influence the financial feasibility of continuous tire pyrolysis projects. Many regions offer tax breaks, subsidies, or grants to encourage investments in sustainable waste management. Regulatory bodies increasingly mandate the proper disposal of waste tires, positioning pyrolysis as a compliant, eco-friendly solution. Navigating these regulations and leveraging incentives can substantially improve the investment outlook of a tire pyrolysis plant.

By reducing waste tires in landfills and transforming them into usable products, continuous tire pyrolysis plants align with environmental policies, making them attractive to eco-conscious investors. Compliance with environmental regulations and the acquisition of necessary permits are essential for long-term operation, ensuring stability and sustainability.

Return on Investment and Payback Period

The return on investment (ROI) of a continuous tire pyrolysis plant depends on factors such as production capacity, byproduct sales, and operating efficiency. Due to continuous processing, these plants generally have shorter payback periods than batch systems, often ranging from two to five years. Higher production capacity allows the plant to generate larger quantities of valuable byproducts, enhancing profitability.

A well-located plant with easy access to tire supplies can further reduce transportation costs, boosting overall profit margins. As demand for alternative fuels and recycled materials grows, the value of pyrolysis byproducts is likely to increase, offering an opportunity for higher returns over time.

Key Considerations for Investors

- Location: Proximity to raw materials, such as waste tires, and accessibility to target markets for byproducts are critical for profitability.

- Technology Partner: Selecting a reputable manufacturer with proven technology is essential. The cost of a tire pyrolysis plant varies widely by technology; a dependable system minimizes risks associated with downtime and maintenance.

- Scalability: A modular approach allows for capacity expansion, accommodating market demand growth without extensive additional investment.

- Operational Efficiency: Choosing a system with advanced automation capabilities reduces labor requirements and minimizes operational costs.

- Environmental Compliance: Ensuring compliance with regulations not only avoids legal complications but also attracts potential investors interested in sustainable solutions.

The Cost Factor: Balancing Expense with Long-Term Gains

When evaluating the cost of a continuous tire pyrolysis plant, prospective investors must consider long-term financial benefits against the upfront expense. While high-quality equipment from a reliable manufacturer may require a larger initial investment, the operational efficiency and durability of these systems can offset costs over time. With a longer operating life and reduced need for frequent maintenance, well-chosen pyrolysis equipment supports long-term profitability. If you want to find a reliable manufacturer, please visit: https://www.bestongroup.com/

Investors should be cautious of low-cost, lower-quality systems that may compromise operational efficiency and incur higher maintenance costs, ultimately impacting ROI. A thorough cost-benefit analysis and due diligence in selecting the right equipment are critical steps for securing profitability.

Conclusion

Continuous tire pyrolysis plants represent a forward-looking investment opportunity that aligns with environmental goals and the increasing need for sustainable waste management solutions. These plants offer promising ROI potential, thanks to rising demand for alternative fuels and recyclable materials, alongside improved operational efficiencies. By carefully considering location, technology, and compliance, investors can tap into the economic and environmental benefits of continuous tire pyrolysis.