Waste tyre is considered to be one of the leading causes of extreme water and soil pollution. Recycling tyre in UK is one solution to decrease tyre waste pollution in the environment. This method of recycling tyre is the method of breaking down the tyre into scrap and retrieving the useful parts for further manufacturing by the famous pyrolysis plant UK. After the resin and chemical structures in the tyre are melted and recycled, this allows new fibers that can be created. Waste tyre to fuel conversion can then be completed.

When outdated tyre products are recycled, it requires less energy. As a matter of fact, only 40% of the energy required to manufacture new products is required for recycled products.

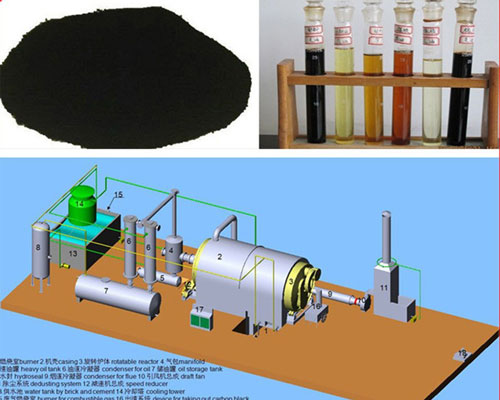

Waste Tyre To Fuel Conversion Machine with PLC

What Are The Negative Effects Of Tyre in UK

There are several negative effects that tyre has on the environment. Some of these effects include:

*Tyre bags are capable of killing animals

*There are some tyre materials are non-biodegradable

*Tyre bags are an eyesore

*Tyre bags are considered pollutants because petroleum is used in tyre production

These are some of the reasons why tyre pyrolysis plant is essential for reducing carbon footprints and conserving energy. Or you take a mobile pyrolysis unit to start business.

Convert Tyre to Fuel

The Advantages Of Waste Tyre Recycling in UK

When tyre is recycled, it can save up to four barrels of oil every day. Oil prices can fluctuate, and prices can change from day to day. The prices of basic needs such as food, gas and other commodities can also fluctuate. However, by recycling tyre, there will be less oil consumption.

There will also be a decreased in the emission of greenhouse gases. Because there are fewer steps required to recycle tyre, the process takes less energy and causes less pollution. This means that fewer greenhouse gases are emitted into the atmosphere.

Another advantage of recycling tyre to fuel is energy conservation. 12,000 units of BTUs are saved when a pound of PET (Polyethylene terephthalate) bottles are recycled. Know oil sludge pyrolysis plant cost from Beston Machinery, the best manufacturer of tyre to oil machine here.

Landfills can also get much needed relief. One of the largest environmental issues facing the planet is that there are no places to dump waste tyre. However, the most effective way to combat this issue is to reduce the amount of tyre that is dumped by recycling.

How Can Recycled Tyre Be Used?

There are some products that are made from recycled tyre including:

*PVC pipes

*Window frames

*Flooring

*CD cases

*Garden furniture

*Seed trays

*Office accessories

By using the tyre to oil machine, waste tyre can also be converted to fuel. Unwashed waste tyre creates the ultimate clean fuel. By diverting tyre from landfills, it will help reduce the amount of dependency on fossil fuels.

However, it is a method that is preferred because 25% of all dumping grounds can be recovered if tyre waste is recycled.

Waste tyre to fuel conversion is a great strategy to save our environment from pollution. It is also an effective way to preserve the planet non renewable energy sources.