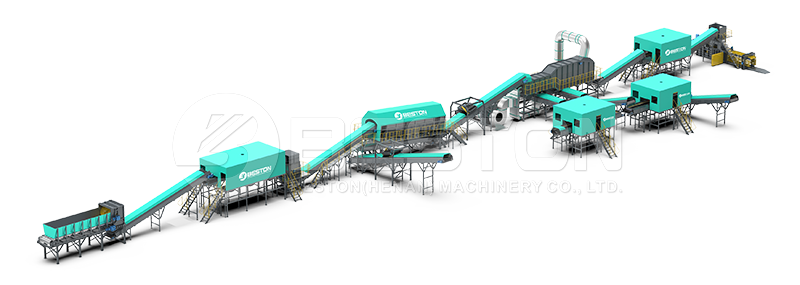

Mini concrete mixing plants (мини заводы бетона) have really changed in recent years. Advancements have been made to increase their productivity capabilities. They will mix a wider range of aggregate material, and will produce concrete that is ready to pour within minutes. Whether you are looking for a large one, or one of the miniature models, there are companies that sell these every day. Prices are going to vary depending upon the make, model and style that you purchase. There are always ways to save money when you are making this type of purchase. To find a business that will sell mini concrete mixing plants, this is what you need to do.

Mining Concrete Batching Plants For Sale

Why You Need To Own A Miniature Concrete Plant

If you need to own one of these, it is likely that you have a business that will take on a multitude of different jobs. Some people prefer having a stationary concrete plant that can produce the concrete that they need that will be delivered in concrete mixer trucks. Others would prefer driving to the location. This will make it easy for you to complete jobs that would otherwise require bringing multiple cement mixing trucks. There are other reasons to bring them. You might be working on a larger job site where concrete is being poured in several different areas. It will be more efficient to simply have these mini concrete pumps positioned where they can be used continuously.

Can You Get Good Deals On These Concrete Pumps?

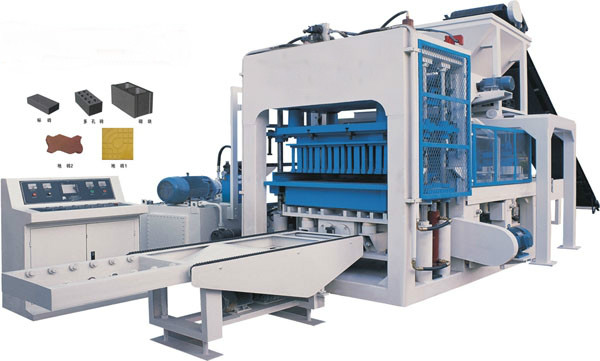

You can get an excellent deals on these concrete pumps. Businesses that sell them (Компании,которые продают бетонные заводы) will often produce several different models. It is important to know a little bit about them so that you will choose the right one for your particular project. This will help you save money, and also get one that will last for quite some time. Research involves looking at each one of these units in detail. You might want to start with the hopper capacity. This will determine how much aggregate material and cement you can determine how much concrete can be made with each batch. The concrete cylinder diameter also needs to be reviewed, along with the max aggregate diameter for the screen. The max theoretical concrete output is often the most important concept to consider as it will pertain to the concrete delivery.

Mini Concrete Batching Plant 35 m3/h

How To Know You Have Purchased The Right One

There are just a few reasons that you should get one of these. You need a new one, or you need to expand your business. You will know that you have made the right purchase because it will help your business generate more revenue. The speed at which the batching plant will produce the concrete (производить бетон) is so important. This includes the maximum horizontal and vertical distance delivery. Also of importance is the concrete pumping pressure, the energy behind the flow of the material to its destination. If all of this is working properly, you should complete jobs quickly and be able to take on more. They are very useful units to have, even for larger businesses.

If you need to find a company that will sell a mini concrete mixing plant to you, online resources are available. Whether you are using the search engines or looking on well-known international websites that sell industrial equipment, you will find what you need. You now know what to look for in regard to the specs and parameters that each of these units will have. Based on that information, and the type of business that you need it for, you will make the right choice. Delivery times can vary, but once it arrives, it will certainly help you improve your business productivity. If you want to learn more useful informations about mini concrete mixing plant, you can visit this website: https://batchingplant.ru/mini-concrete-plant/.