An egg tray making machine is used to create sturdy, molded egg trays from a paper pulp mix. In daily life, egg trays are used to protect eggs from water damage and breakage during transportation and storage. As a result, the global demand for such manufactured food packaging is high. According to many investors in India, starting an egg tray manufacturing business in the region can generate high, consistent annual profits. The good news is that setting up an egg tray making machine in India is easier and cheaper than ever thanks to the internet. There are machines in the marketplace that can output over 6000pcs an hour on a continuous basis.

Egg Tray Machine in India

Raw Materials

So, what are egg cartons and egg trays made from? Well, it is possible to use any type of paper-based waste to manufacture pulp molded egg trays, including waste newspapers, waste books, and scrap paper. The cost of the raw materials is very cheap, as lots of countries have mounting waste disposal and recycling problems to cope with. Of course, egg cartons can also be manufactured from plastic, but plastic food packaging is not very environmentally friendly and it is more expensive to produce. There is a ban on plastic packing products in India as well. So paper egg tray making machine in India will be a very promising business.

Egg Tray Machine Suppliers

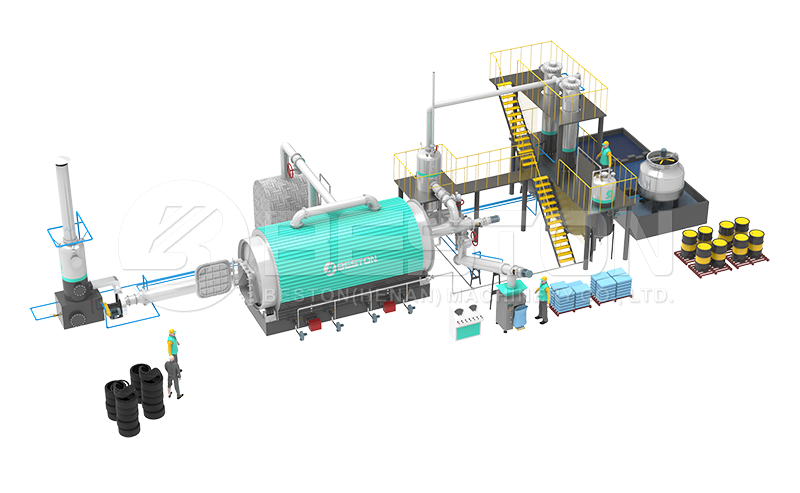

Leading egg tray machine manufacturers, such as Beston Machinery, service the global market space and they have customers in Egypt, Dominica, Russia, Brazil, Australia, India, South Africa, Uganda, Netherlands, the Phillippines and more. Such suppliers have years of experience in the international export industry, so they know how to ensure their overseas customers get the machines they order in a timely manner. You can find hundreds of success cases of people around the world setting up egg tray manufacturing businesses by investing in the best paper pulp molding machine, such as egg carton making machine.

Egg Tray Molds

Manufacturing Processes

There are four key stages of the egg tray manufacturing process, pulp making, molding, drying, and packing. During the first stage, a rough pulp is created by adding a mixture of paper waste materials into a hydraulic pulper and adding water. The rough pulp is then refined using a homogenization pool and pulp beater.

Model Specifications

Different egg tray making machines have different specifications. Some of the key specs to compare include forming mold quantity pieces, total power, electricity consumption, capacity (pcs/h), working method, labor force requirements, material consumption (kg/h), fuel consumption and price. Often you will have to contact suppliers directly top obtain price quotations for different models. The good thing about fully automatic egg tray making machine is that they require a very limited manual workforce and can operate 24/7. Of course, fully automatic models require a larger initial investment than manual egg tray machine.

When comparing prices it’s important to take into account transportation charges, import charges, and installation charges. You will need to inform the supplier of your port and shipping requirements to receive an accurate price. The installation charge is usually an optional add-on, as many businesses may not require an engineer from the manufacturer’s headquarters to help with setup and operation training. The complexity and the estimated duration of the installation process will affect the total cost.