Do you have demand for tire recycling plants for sale? Tires of all types make it into landfills, and for quite some time, the problem was getting worse. Yet more and more companies are discovering great ways to safely recycle the tires, understanding the importance of this movement. These tires aren’t trash, as they can be recycled and turned into treasure that can be sold for a profit. Are you ready to take a look at tyres recycling plant?

There are all types of tires out there. Agricultural tires and truck tires are some of the largest. There are car tires, off-road tires and radial tires, too. Which do you have on hand? Maybe after starting a recycling effort, you could even reach out to your community to get even more tires into your pyrolysis plant.

Installation of Beston Tires Recycling Plant

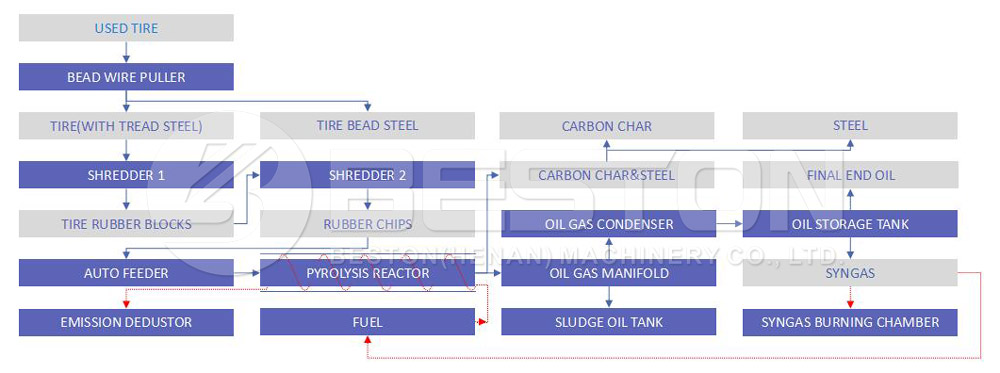

Are you familiar with the process of pyrolysis? This is one type of tire recycling that is increasing in popularity. You do have other choices, but many people point to the fact that this type of plant is the best solution. With a continuous pyrolysis plant, you are able to recycle tires 24/7. Besides, the oil sludge can be handled by this machine. Go on https://bestonturkey.com/oil-sludge-pyrolysis-plant/ to find your ideal machine.

What does your business get by taking on the purchase of one of these plants? Carbon black is one of the byproducts that is generated from this process. This substance is used in the making of all kinds of products. So if you’re not able to use the carbon black yourself, you should easily be able to find a buyer.

Good Feedback for Beston Tire Recycling Plants For Sale

This plant is going to run itself, too, because it uses some of the pyrolysis oil for fuel. Therefore, once you make your investment, it’s all profit from there. Each time you sell carbon black, you are making money. How long is it going to take in order for you to pay yourself back for the purchase of the plant.

That’s a good question, and you’re going to want to do some calculations in order to determine the answer based on your business and how many tires you will be recycling. One thing you need to know is that you get more than just the profits from the carbon black.

These tire recycling plants for sale come in all sizes, and you want to determine which machine capacity is going to suit your business best. Remember that if you get a continuous plant, you can feed it waste tires 24 hours a day. Does the pyrolysis process represent the choice you want to make when it comes to recycling tires? You can certainly examine your other options and see what the best decision is for your company. This manufacturer, Beston Machinery China, will make an appropriate proposal for you.