Do you want to start your own business? Are you searching for a highly profitable business opportunity? If that is the case, you should seriously consider investing in an egg tray making machine. You might be wondering why investment in such a basic product could be a highly profitable business opportunity. Here is what you need to know about an egg tray machine.

Egg Tray Machine

First and foremost, let’s discuss the demand for paper trays in today’s economy. These days, consumers expect things to be well organized. Everything needs to neatly packed and wrapped in order to attract consumers. Companies selling products have recognized this need and now these companies, pay special attention to the presentation. This is where paper egg trays and similar products come into picture. These products have seen a huge surge in demand due to the changing preferences of consumers. Therefore, it also offers an excellent opportunity for enterprising individuals like you looking to take advantage of this changing consumer trend.

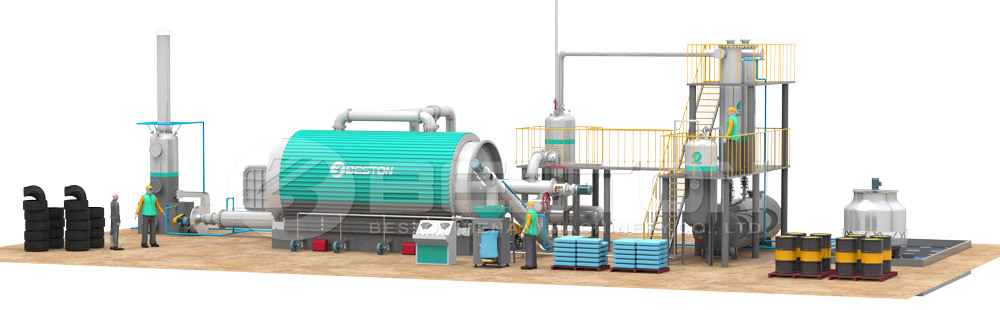

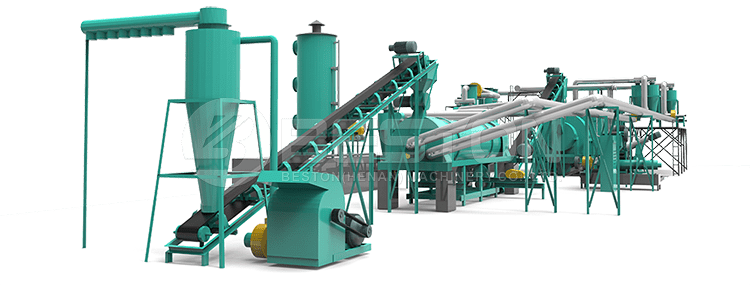

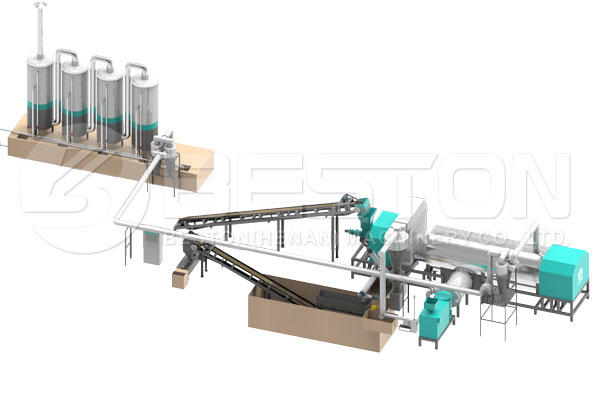

On the surface, the process of making egg trays seems very simple. You take raw material, prepare it in the form of a slurry and put it in a mold and pressurize the mold to get the kind of tray you want. However, there are a lot of things that can go wrong in this process and therefore, you need to pay special attention to the machine used for this business. Don’t expect that manual egg tray machine available for sale in the market for making egg trays as well as other paper trays is the same. There is a lot of difference in terms of efficiency, capacity, types of mold that can be used in a machine, level of automation, labor requirement, power requirement, water requirement and a whole lot of other things. Therefore, before you buy a machine, prepare a business plan.

This business plan should cover a whole lot of things. You should begin by considering the cost of the land. Take into account the cost of the egg carton machine, cost of labor, cost of raw material and more importantly, availability of raw material, demand for finished products, contracts with buyers, logistics in place to get the raw materials and to supply the finished product, availability of water at the plant site, availability of power at the plant site, and many other such things. Only after you have a very well thought out business plan, you should consider buying a machine. It will save you a lot of money and a lot of trouble down the line.

Egypt Egg Tray Machine In Container

When it comes to buying the machine, you should consider offerings from your local vendors and overseas vendors. Don’t make the mistake of sticking to only the local vendors as overseas lenders have invested a lot of money in research and development which means you can trust them when it comes to quality of materials used for making the machine as well as after sales service. However, not all the overseas vendors are the same and take their reputation seriously. Therefore, when it comes to choosing vendors, choose someone who has a service office in your country and has a good reputation in the industry for supporting their products after the sale.

Overall, investment in an egg tray making machine can be a profitable opportunity provided you prepare a well-researched business plan. Keep the above mentioned tips in mind when buying a machine (https://eggtraymakingmachine.net/egg-tray-making-machine-price/) for making paper trays to get the best value for your money.