Do you need a stationary concrete pump (стационарный бетонный насос), one that can replace the unit that you have right now? If you need to have this immediately, you should be able to find a used model somewhere in your immediate area. However, if you are not in a rush, and you would like to save money, there are strategies you can use to find these concrete pumps that are very reasonably priced. To obtain one that is stationary, that will pump all of your concrete efficiently, here is how you can find low prices on some of the top models.

Stationary Concrete Pump Cost

Why Would You Need A Stationary One?

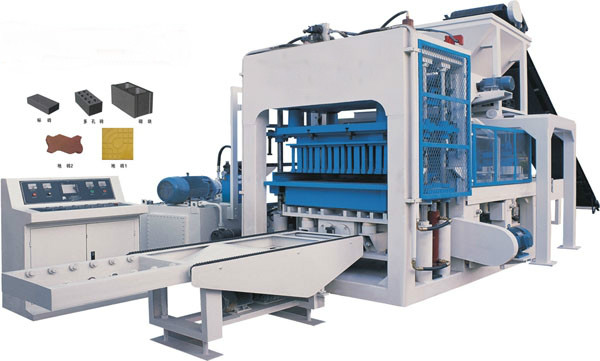

The main difference between a trailer (прицепной бетононасос) or mobile concrete pump, and a stationary one, usually has to do with capacity. They are typically designed to process more concrete, often made to load concrete mixers that will be taken to job sites. These pumps typically cost tens of thousands of dollars and are capable of delivering thousands of gallons of concrete every single day. Therefore, their primary purpose is to pump concrete into mobile units or storage bins, but you must choose one that has the best specifications.

Concrete Pump Specifications To Consider

There are many things to consider before purchasing stationary concrete pump. You need to consider the pumping pressure, the conveying capacity, and the maximum delivery distance. Also look at the distributing valve form, the concrete cylinder size, and the concrete hopper that is used on each model. When looking at the power system, which could be diesel or electric, look at what it is rated for in regard to power and speed. Evaluate the hydraulic system that is used, specifically the main oil pump, it’s delivery capacity, and the maximum pressure of its distributing system.

Stationary Concrete Pumps For Sale

How To Save Money On Your Purchase?

If you search on websites like AliBaba, this is where you can locate some of the top manufacturers (производители) that are offering extremely low prices. You will see deals that can save you a substantial amount of money, but most of these offers are from companies in different countries. If you purchase one from China, for instance, it may take a few weeks to arrive. However, the cost savings of purchasing one from the Orient, regardless of the shipping cost, will motivate any contractor to have one shipped from overseas. Once you have found the best one, you should place your order and have it shipped right away. Your evaluation of each stationary concrete pump that you find will help you locate the best one for your business.

The stationary concrete pump that you purchase should be one that is comparable to, or better than, the one that you have right now. If you do not have one, then consider all of the specifications that were mentioned before making your purchase. By making sure that you are getting one that can handle all of the concrete (Бетон) that you need to produce, this is going to help your business grow. It is an essential component of any industrial or commercial business that is consistently using concrete to complete their projects.