The main aim of this work is an evaluation, on a pilot scale, of scrap tire pyrolysis process production and also the features of the products under different process parameters, such as temperature, residence time, pressure, etc. In this casing, a progression of tests was done at different procedure temperatures somewhere around 550 and 680 C, other parameters being equivalent. A securing framework gathers tyre recycling process information; scrap tire tests utilized for the treatment, solid and fluid by-items and created syngas were dissected through both on-line monitoring (for gas) and laboratory investigations. Results demonstrate that procedure temperature, in the explored range, does not appear to impact the volatilisation response yield truly, in any event from a quantitative perspective, while it noticeably impacts the dissemination of the unpredictable portion (fluid and gas) and by-items attributes.

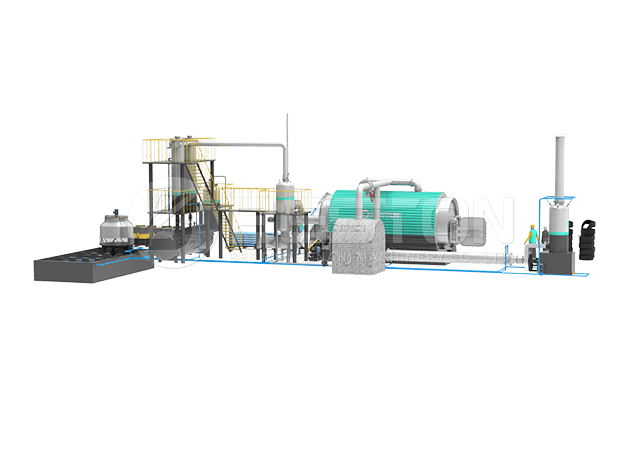

Tyre Recycling Plant

Presentation

The world generation of waste tires adds up to 5×106 ton/year; that is 2% of aggregate solid waste creation for one year

Indeed, even today, the last destination of almost 65–70% of waste tires is the landfill, legitimate or illicit; yet this “solution” is by all accounts not all that profitable to the extent the high included worth materials misfortune, and the ecological effect is concerned.

Medications contrasting option to landfilling, ready to absorb right around 25% of this sort of waste, consider the tires’ recreation and reuse or the matter and vitality recuperation by a method for thermal treatment procedures, of which the more important are incineration, gasification, and pyrolysis project. They differ from each other as for operational conditions and, thus, handle by-items.

Among the thermal demolition advancements, the pyrolysis procedure is by all accounts more alluring in comparison with the other medications as far as minor natural effect. The procedure gives, as by-items, gasses, oils, and singe (solid buildup) that, after the suitable redesigning treatment, may have high included quality through making them accessible in the business sector.

Continuous Tyre Pyrolysis Plant to Romania

Some seat or pilot scale different specialists have as of now reported exploratory studies on the transfer of scrap tires, however, numerous issues are still a long way from a solution. Get the latest Beston pyrolysis machine price now.

The principle target of the examination work in advancement is to assess both procedure performance and qualities of the items acquired while working the tire pyrolysis plant under different operational parameters, for example, temperature, living arrangement time, weight and so on. An endeavor has been made to lead an arrangement of examinations under different loads and changing procedure temperature. Scrap tire tests utilized for the treatment, solid and fluid by-items and syngas created were broke down through both on-line monitoring (for gas) and laboratory investigations, and the results are discussed in the present paper.

Pyrolysis Process

There are three main thermal conversion methods: incineration, gasification, and pyrolysis. They differ from each other on operational conditions and consequently process by-products.

While the incineration process totally burns the material, developing in situ its energy content, the other techniques (i.e. gasification and pyrolysis) are aimed at material recovery by transforming the waste into carbon-, raw petroleum- or natural gas-like products. These materials could be used as such, or be converted and upgraded to higher value products, fuels, and chemicals

Pyrolysis is a warm corruption process in which the material is warmed in a roundabout way in a sans oxygen air. The entire tire pyrolysis process is the aggregate of a progression of parallel and ensuing responses that occur in the pyrolysis reactor. The items create and respond as per the equilibria that occur in the reactor. So the worldwide pyrolysis response that happens in a reactor can be portrayed in an accompanying way:

Organics→volatile matter+solid residue.

Organic material, fed to the pyrolysis reactor then undergoes a thermal cracking, by cleaving itself into a volatile fraction and a solid residue.

The volatile fraction can be cooled and partially condensed, thus obtaining two fractions: a liquid fraction and a gaseous uncondensable fraction.

Normally, the process provides as by-products:

a gaseous fraction, essentially composed of hydrogen, methane and carbon oxides;

a liquid fraction, composed of water, tar and oils (organic compounds);

Yields and compositions of the three fractions depend on process parameters values (temperature, heating rate, pressure, residence time, material granulometry) and volatile fraction condensation temperature.

(1) Safety.

We consolidate into the plant some safety devices like safety valve, pressure gage system and alarming ring. Other than that there is additionally we anti-back fire appliance that can ruin fire over into the reactor.

(2) Environment securing.

The running plant is planned and created with the gear like Dust-gathering System that beats the difficulties identified with water and air contaminations with the gadget to dissipate vapor so as to keep nature clean and empowering.

(3) Energy sparing.

Against back-fire device is consolidated so as to gather the pipe gas as oil is released, therefore the sparing of vitality. In the meantime, the plant has a catalyst chamber that can diminish the temperature of the reactant pyrolysis of tyres and plastics, subsequently sparing a decent measure of vitality. Other than that there is likewise vacuum device in the plant that permits the reactor to apply negative weight.

(4) High-productivity of programmed procedure.

The plant is exceedingly robotized for completing some vital demonstrations with the assistance of specified beneath gear and gadgets incorporating auto-sustaining, carbon black elevator, automatic oil pumping, automatic pressure regulator.