Hydraulic metal bending machines are uniquely built to bend bars into precision for ornamental purposes. These machines come in handy in wrought iron gate and fence construction where contractors should shape crafts/metal bars fit and healthy. Even though market may be flooded with various types of hydraulic bending machines, most contractors and experts prefer the low price hydraulic metal craft bending machine to the others. A primary reason just for this is the fact these hydraulic systems do not only bending scrolls and steel bars. Some of the reasons and advantages of using a hydraulic bar bending machine are discussed below.

1. Doubles as metallic press

The wonder in buying a hydraulic metal bending machine http://ellsenwroughtironmachinery.com/ is the fact that device will take over press functions efficiently, hence no need to invest in a brake press. Another added advantage within this is the system could be configured into profiles that will make bending metals in different profiles superior to when working with a press. The hydraulic system also provides an upper beam that enables compressing bent sheets for folding.

2. No tool changes needed

While non-hydraulic metal bending machines require tool change to meet most profiles, a hydraulic system can achieve a variety of profiles without necessarily being forced to change tools. This is especially crucial for round bending in which the metal has to be bend with a certain radius. The hydraulic metal bending machine allows adjusting the bending angle for efficiency. Another added benefit of utilizing the hydraulic system is the end result of round bending is a smooth curved surface as compared with segmented steps on brake presses.

3. No additional holding devices needed

A hydraulic metal craft bending machine works on metal sheets when in a resting position. This means you don’t need other devices to keep the metal crafts in place. Furthermore, the sheets are bent inside a natural position which makes bending a relatively simple and smooth process. The same can not be said about brake press that require some assistance?to take care of long sheets of metal.

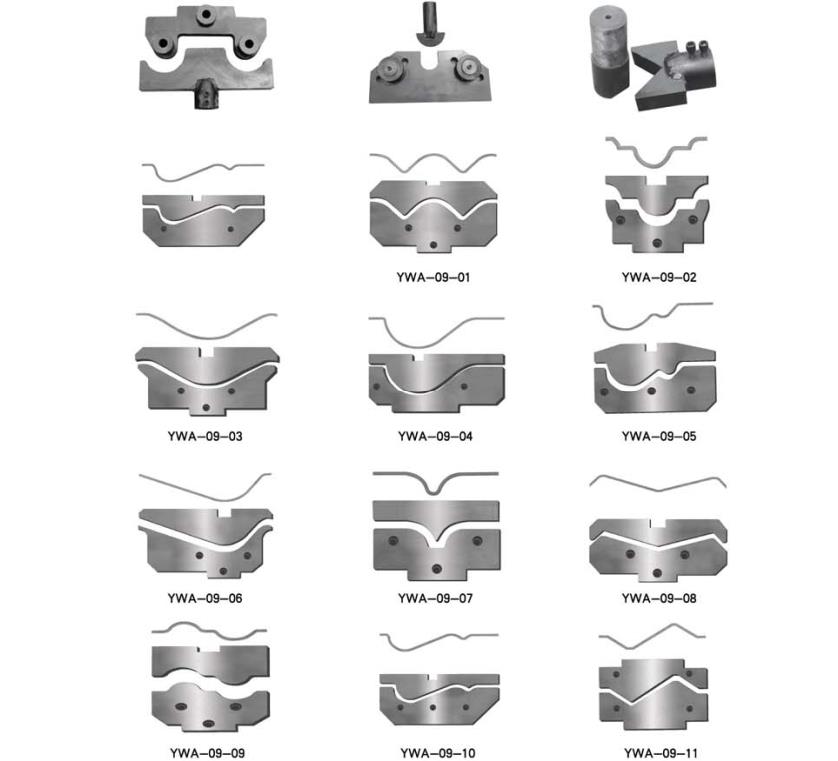

Hydraulic bending machine molds

4. An easy task to operate

The hydraulic system could be operated single-handedly by an individual. Here is the website http://www.ellsenwroughtironmachinery.com/wrought-iron-hydraulic-bending-machine/, for your reference. This means you never have to employ more people to help you together with the bending, as being the single individual can oversee calibrations and even feed the bending machine easily. Apart from this, experts can program the program to deal with bending jobs based on their preset profiles. This means you get to reduce both time and money from buying these systems.

Although these hydraulic systems may be useful within your brand of work, it could be advisable to perform a little research with a machinery manufacturer or supplier before making an order for the same. Checking how much time the producer has been doing business, warranty, durability, and service guarantee would have been a wise move at the same time. These machines can be found in various sizes and capabilities, meaning you have to purchase the most appropriate one depending on your contracts. Getting an expert assist you with the selection process would also be a welcome idea.