The waste plastic pyrolysis equipment is a perfect equipment utilized for recycling waste plastics. It embraces the most recent pyrolysis innovation by which plastics can be completely changed over into valuable assets. Is it nice to know plastic recycling plant price?

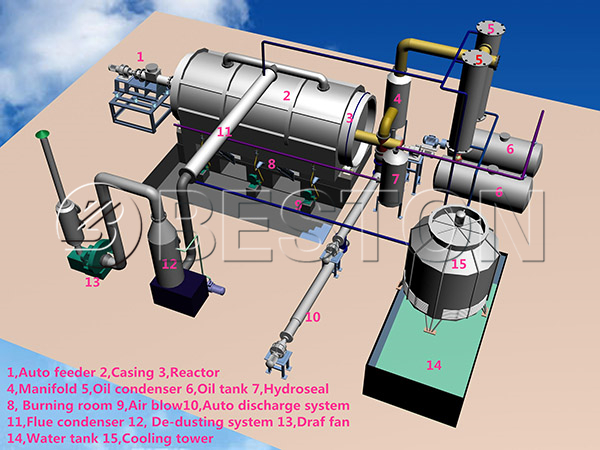

Beston Waste Plastic Recycling Pyrolysis Equipment

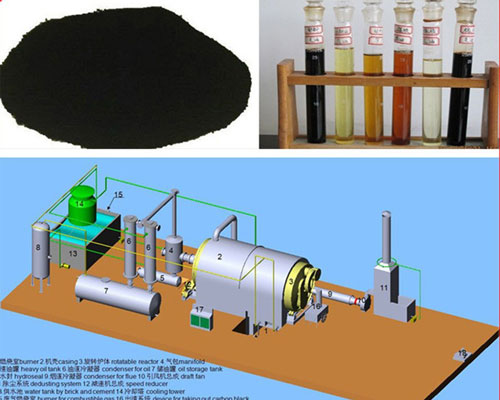

The pyrolysis procedure is exceptionally basic and straightforward. It alludes to the warm decay of waste plastics at high temperature without oxygen. Completely fixed outline can promise the entire procedure is extremely environment neighborly. At the point when the procedure is done, we can get plastic oil, carbon dark and somewhat burnable gas. And all the deciding items have an extensive variety of uses.

Is it good to know first recycling waste plastic pyrolysis plant price? The plastic oil can be utilized as fuel oil as a part of numerous commercial ventures and can likewise be refined to diesel oil. The carbon dark can be used for making development blocks with earth or utilized as fuel. By the additional gas recycling framework, the flammable gas will be reused to warm the reactor as fuel, which will spare vitality for the entire recycling procedure of plastic.

As we as a whole know, when the oil gas, oxygen and high temperature combined in the working process, a shocking blast will be liable to happen. So develop security gadget is the assurance for the ordinary operation of the plant. Having been in this field, all of the plants are outfitted with cutting-edge security gadgets, for example, the auto alert framework for over temperature and weight, auto weight discharging framework for crisis circumstances and putting out fires gadgets, etc. These wellbeing gadgets can promise security 100% in the generation procedure.

The waste plastic recycling pyrolysis equipment price have diverse working frameworks and beneficiary handling limits range from 6 ton to 50 ton for every day. If you have exceptional interest, we can likewise give you redid item.

Waste Plastic Pyrolysis Production Process

The blended waste plastics will be destroyed and consistently encouraged into the pyrolysis reactor using sustaining machine. The materials will be pre-warmed amid the passing on the procedure, and the low liquefying point plastic like PVC will be pyrolysed. The HCl will be then killed treated after detachment with different materials.

The steady temperature warming framework supplies warmth to the pyrolysis reactor. The crude materials are persistently encouraged into the pyrolysis reactor and spread by the framework, finishing pyrolysis response with the high-effectiveness impetus.

The pyrolysis oil gas is transformed into brilliant fuel oil and a little measure of ignitable gas in the wake of taking after procedures, for example, partial refining detachment, settled bed optional gas catalyzing and de-waxing and so forth.

Plastic Pyrolysis Equipment For Sale

The burnable gas is ultimately utilized as fuel to the framework in the wake of scouring, which accomplishes heat vitality self-supporting. The gas in the wake of being copied will be qualified released after the gas cleansing procedure.

The little measure of strong buildup created from the response is always released out of the reactor, and that could be further prepared into fuel stick.

Frameworks of pyrolysis plastic waste recycling plant

- Waste plastic pre-treatment framework;

- Crude material pre-warming framework;

- Steady temperature warming framework;

- HCl retaining structure (discretionary relying upon material);

- Nonstop pyrolysis framework;

- Ignitable gas cleaning framework;

- Gas filtration framework;

- Leftover dirty free treatment framework;

- Control subsystem